“Fixing mistakes one piece at a time.”

Common Mistakes to Avoid During Disassembly

Taking apart a device or piece of equipment can be a daunting task, especially if you’re not familiar with the inner workings of the item. Whether you’re attempting to repair a malfunctioning appliance or simply trying to clean out dust and debris, disassembly can quickly turn into a frustrating experience if you’re not careful. In this article, we’ll discuss some common mistakes to avoid when taking things apart, and offer some tips for troubleshooting the takedown process.

One of the most common mistakes people make when disassembling something is not properly documenting the process. It’s easy to get caught up in the moment and start pulling things apart without keeping track of where each component belongs. This can lead to confusion and frustration when it comes time to put everything back together. To avoid this, be sure to take plenty of pictures before you start disassembling anything. You can also use small containers or bags to store screws and other small parts, labeling each one with the corresponding step in the disassembly process.

Another common mistake is using the wrong tools for the job. While it may be tempting to grab whatever tool is closest at hand, using the wrong tool can cause damage to delicate components or make the disassembly process much more difficult than it needs to be. Before you start taking things apart, take the time to gather the proper tools for the job. This may include screwdrivers, pliers, and other specialized tools depending on the item you’re working on.

One of the biggest challenges when disassembling something is dealing with stuck or stubborn components. Whether it’s a rusted screw or a tightly sealed casing, getting stuck can quickly derail your disassembly efforts. If you encounter a stubborn component, resist the urge to force it apart. Instead, try using a lubricant like WD-40 to help loosen things up. You can also try tapping gently on the component with a hammer to help break it free. If all else fails, consider seeking help from a professional to avoid causing further damage.

Another common mistake people make when disassembling something is not following a logical order. It’s important to have a plan in place before you start taking things apart, so you don’t end up with a pile of parts and no idea how to put them back together. Start by identifying the main components of the item and work your way down from there. Take note of how each piece is connected to the next, and be sure to keep track of any screws or fasteners you remove along the way.

In conclusion, disassembling something can be a challenging task, but with the right approach, you can avoid common mistakes and troubleshoot any issues that arise along the way. By documenting the process, using the proper tools, dealing with stuck components effectively, and following a logical order, you can make the takedown process much smoother and more successful. Remember to take your time and be patient, and don’t hesitate to seek help if you run into any roadblocks. With a little bit of planning and preparation, you can tackle any disassembly project with confidence and ease.

How to Fix Broken Parts During Takedown

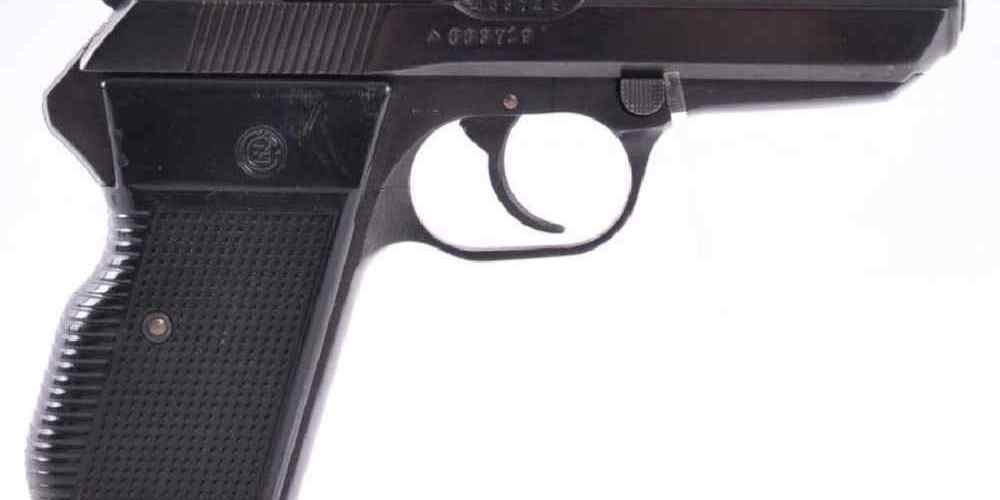

Taking apart a firearm for cleaning or maintenance is a routine task for many gun owners. However, sometimes things don’t go as planned, and parts can break or become damaged during the disassembly process. In this article, we will discuss common issues that can arise during takedown and provide tips on how to troubleshoot and fix broken parts.

One of the most common problems that gun owners encounter during takedown is stripped screws. This can happen when too much force is applied while trying to remove a screw, causing the head to become damaged and difficult to grip. If you find yourself in this situation, there are a few tricks you can try to remove the stripped screw. One method is to use a rubber band or a piece of duct tape to create more friction between the screwdriver and the screw, allowing you to turn it with more ease. Another option is to use a screw extractor tool, which is specifically designed to grip onto stripped screws and remove them.

Another issue that can occur during takedown is a broken or damaged pin. Pins are used to hold various parts of the firearm together, and if one becomes bent or broken, it can prevent the gun from functioning properly. If you encounter a broken pin during disassembly, you may be able to replace it with a new one. However, if the pin is stuck or difficult to remove, you may need to use a punch and hammer to carefully tap it out. Be sure to use caution and take your time to avoid causing further damage to the firearm.

Sometimes, gun owners may accidentally lose a small part during takedown, such as a spring or detent. If this happens, don’t panic – there are ways to replace lost parts. One option is to check with the manufacturer of the firearm to see if they sell replacement parts. You can also search online for gun parts suppliers who may carry the specific part you need. Additionally, some gunsmiths may be able to fabricate a replacement part for you if necessary.

If you encounter a broken or damaged part during takedown and are unable to fix it yourself, it may be time to seek professional help. Gunsmiths are trained professionals who specialize in repairing and maintaining firearms. They have the knowledge and tools necessary to diagnose and fix a wide range of issues, from broken parts to malfunctioning mechanisms. If you are unsure of how to proceed with troubleshooting a broken part, don’t hesitate to reach out to a gunsmith for assistance.

In conclusion, troubleshooting broken parts during takedown is a common challenge that many gun owners face. By following the tips and techniques outlined in this article, you can effectively address issues such as stripped screws, broken pins, and lost parts. Remember to take your time, use caution, and seek professional help if needed. With a little patience and know-how, you can successfully troubleshoot and fix broken parts during takedown, keeping your firearm in top condition for years to come.

Troubleshooting Tips for Stuck or Jammed Components

Taking apart a firearm for cleaning or maintenance is a routine task for many gun owners. However, sometimes things don’t go as smoothly as planned, and components can become stuck or jammed during the disassembly process. In this article, we will discuss some common issues that can arise when trying to take down a firearm and provide some troubleshooting tips to help you overcome these challenges.

One of the most common problems gun owners encounter when disassembling a firearm is a stuck or stubborn takedown pin. This can happen for a variety of reasons, such as dirt or debris blocking the pin’s movement, or the pin being bent or damaged. If you find yourself struggling to remove a takedown pin, try applying some lubricant to the pin and gently tapping it with a hammer or mallet to help loosen it. If the pin still won’t budge, you may need to use a punch or other tool to carefully pry it out.

Another issue that can arise during disassembly is a jammed slide or bolt. This can occur if the slide or bolt is not properly aligned with the frame or receiver, or if there is debris or fouling preventing it from moving smoothly. If you are having trouble removing the slide or bolt from your firearm, try cleaning the area around the slide or bolt and applying some lubricant to help loosen it. You may also need to gently tap the slide or bolt with a hammer or mallet to help free it from its stuck position.

Sometimes, the problem may not be with a specific component, but rather with the overall disassembly process. If you are having trouble taking apart your firearm, take a step back and carefully review the manufacturer’s instructions for disassembly. Make sure you are following each step correctly and in the proper order. It can be easy to overlook a small detail or skip a step, which can lead to components becoming stuck or jammed.

If you are still unable to disassemble your firearm after trying these troubleshooting tips, it may be time to seek professional help. Taking apart a firearm can be a delicate process, and attempting to force stuck components can cause damage to your gun. If you are unsure of how to proceed or are concerned about causing further damage, it is best to consult a qualified gunsmith or firearms expert for assistance.

In conclusion, troubleshooting a stuck or jammed component during the disassembly of a firearm can be frustrating, but with patience and the right tools, you can overcome these challenges. By following the tips outlined in this article and taking a methodical approach to disassembly, you can ensure that your firearm remains in good working condition and ready for use. Remember, when in doubt, seek professional help to avoid causing further damage to your gun.

Preventing Damage to Your Equipment During Disassembly

Taking apart equipment can be a daunting task, especially if you’re not familiar with the inner workings of the device. However, with the right tools and knowledge, disassembly can be a straightforward process. Unfortunately, there are times when things don’t go as planned, and you may end up causing damage to your equipment. In this article, we’ll discuss some common mistakes that people make during disassembly and provide tips on how to prevent damage to your equipment.

One of the most common mistakes people make when disassembling equipment is using the wrong tools. Using tools that are too big or too small for the job can cause damage to delicate components. It’s important to use the right tools for the job to avoid causing unnecessary harm to your equipment. Before you start disassembling anything, make sure you have the proper tools on hand.

Another common mistake is not following the manufacturer’s instructions. Every piece of equipment is different, and manufacturers provide specific guidelines for disassembly. Ignoring these instructions can lead to damage to your equipment. Make sure to read the manual carefully before you start taking things apart.

It’s also important to be gentle when disassembling equipment. Applying too much force can cause components to break or become misaligned. Take your time and work slowly to avoid causing damage. If something seems stuck, don’t force it. Instead, try to figure out why it’s not coming apart and address the issue before proceeding.

When disassembling equipment, it’s crucial to keep track of all the screws and other small components. Losing a screw or misplacing a small part can cause problems when it comes time to reassemble the equipment. Consider using a magnetic tray or small containers to keep track of all the pieces as you take things apart.

Another common mistake is not properly grounding yourself before working on electronic equipment. Static electricity can damage sensitive components, so it’s important to discharge any static buildup before touching anything. Consider using an anti-static wrist strap or mat to prevent damage to your equipment.

If you encounter any resistance while disassembling equipment, stop and reassess the situation. Trying to force something apart can lead to damage. Take a step back and try to figure out why you’re encountering resistance. It’s better to take a break and come back with a fresh perspective than to risk causing damage to your equipment.

In conclusion, disassembling equipment can be a tricky process, but with the right tools and knowledge, you can avoid causing damage. Make sure to use the proper tools, follow the manufacturer’s instructions, be gentle, keep track of all components, ground yourself properly, and stop if you encounter resistance. By taking these precautions, you can prevent damage to your equipment and ensure a successful disassembly process.

Expert Advice on Troubleshooting Takedown Issues

Taking down a firearm for cleaning or maintenance is a routine task for gun owners. However, sometimes things don’t go as planned, and disassembly can become a frustrating experience. In this article, we will discuss common issues that gun owners may encounter when disassembling their firearms and provide expert advice on troubleshooting these problems.

One of the most common issues that gun owners face when disassembling their firearms is getting stuck parts. This can happen for a variety of reasons, such as built-up dirt and grime, improper maintenance, or worn-out components. If you find yourself struggling to remove a part during disassembly, it’s important to remain calm and avoid using excessive force. Instead, try using a lubricant to help loosen the part and gently tap it with a rubber mallet to dislodge it.

Another common issue that gun owners may encounter is losing small parts during disassembly. This can be a frustrating experience, especially if the lost part is essential for the firearm to function properly. To prevent this from happening, it’s important to work in a clean and well-lit area and use a magnetic tray to keep track of small parts. If you do happen to lose a part, don’t panic. Many gun manufacturers offer replacement parts that can be easily ordered online.

Sometimes, gun owners may find that they are unable to reassemble their firearms after disassembly. This can happen if the parts are not put back together in the correct order or orientation. To avoid this issue, it’s important to take notes or pictures during disassembly to help guide you through the reassembly process. Additionally, referring to the firearm’s manual can provide valuable information on how the parts should be assembled.

If you are still having trouble reassembling your firearm, don’t hesitate to seek help from a professional gunsmith. They have the knowledge and experience to troubleshoot any issues you may be experiencing and can help ensure that your firearm is reassembled correctly and safely.

In some cases, gun owners may encounter issues with the functionality of their firearms after disassembly. This can happen if the parts were not properly cleaned or maintained during the disassembly process. To prevent this from happening, it’s important to thoroughly clean and inspect each part before reassembly. Additionally, using a high-quality lubricant can help ensure that the firearm functions smoothly after reassembly.

If you are still experiencing issues with the functionality of your firearm after reassembly, it’s important to seek help from a professional gunsmith. They can diagnose any underlying issues with your firearm and make any necessary repairs to ensure that it functions properly.

In conclusion, troubleshooting takedown issues can be a frustrating experience for gun owners. However, by remaining calm, following proper disassembly and reassembly procedures, and seeking help from a professional gunsmith when needed, you can overcome these challenges and ensure that your firearm is properly maintained and functions smoothly. Remember, safety should always be your top priority when working with firearms, so never hesitate to seek help if you are unsure about how to troubleshoot a takedown issue.