“Unlock the Secrets of Shotgun Shells: Your Ultimate Guide to Components and Craftsmanship”

Understanding the Basics of Shotgun Shell Anatomy

The Comprehensive Guide to Shotgun Shell Components

Understanding the basics of shotgun shell anatomy is essential for both novice and experienced shooters alike. A shotgun shell is a marvel of engineering, designed to deliver a specific payload with precision and reliability. Each component of the shell plays a crucial role in its overall performance, and knowing how these parts work together can enhance your shooting experience and even improve your accuracy.

At the heart of a shotgun shell is the primer, a small but mighty component that ignites the propellant. The primer is typically a metal cup containing a volatile chemical compound that, when struck by the firing pin, creates a spark. This spark is the catalyst for the entire firing process, setting off a chain reaction that ultimately propels the shot towards its target.

Following the primer in the sequence is the propellant, commonly known as gunpowder. Modern shotgun shells use smokeless powder, which is more stable and produces less residue than traditional black powder. The propellant’s role is to generate the explosive force needed to project the shot. When ignited by the primer, the propellant burns rapidly, creating a high-pressure gas that expands within the shell and forces the payload down the barrel.

Encasing the propellant is the shell casing, typically made of plastic with a metal base. The casing protects the contents of the shell and ensures that the expanding gases are directed forward. The base of the casing houses the primer and is often reinforced with a brass head for durability and to provide a secure seat for the primer.

Within the casing, you’ll find the wad, a crucial component that serves multiple purposes. The wad acts as a barrier between the propellant and the shot, preventing the latter from becoming deformed by the explosive force. It also seals the gases produced by the burning propellant, ensuring that they push the wad and shot column uniformly. Additionally, the wad helps to cushion the shot as it accelerates down the barrel, reducing the likelihood of pellet deformation and improving the shot pattern.

The shot, or pellets, is what most people envision when they think of a shotgun shell. These pellets can be made of various materials, including lead, steel, bismuth, or tungsten, and come in different sizes to suit various shooting applications. The size and material of the shot will determine its weight, pattern, and penetration, making the selection of the right shot critical for the intended use, whether it be hunting, target shooting, or self-defense.

Finally, the crimp at the end of the shell casing holds everything together. The crimp can be either a star or roll design and serves to contain the shot until the shell is fired. A good crimp ensures that the shot is securely held in place and that the shell will feed smoothly into the chamber of the shotgun.

In summary, each component of a shotgun shell—the primer, propellant, casing, wad, shot, and crimp—works in concert to deliver a controlled and effective burst of energy capable of hitting a target. Understanding these components allows shooters to make informed choices about their ammunition, tailoring their selection to the specific demands of their shooting activity. Whether you’re aiming for precision in competitive shooting or seeking the right load for a hunting expedition, a solid grasp of shotgun shell anatomy is the foundation upon which shooting success is built.

The Role of Primers in Shotgun Shells: A Deep Dive

The Comprehensive Guide to Shotgun Shell Components

When it comes to the world of firearms, the shotgun stands out for its versatility and power. Central to its function is the shotgun shell, a marvel of engineering that propels a variety of payloads towards a target with remarkable precision. To truly appreciate the ingenuity behind these shells, one must delve into the components that make up their anatomy, with a particular focus on the role of primers—a small but critical element in the firing process.

At the heart of every shotgun shell lies the primer, the unsung hero that ignites the chain reaction leading to the discharge of the firearm. Primers are essentially the spark plugs of shotgun shells, providing the initial burst of energy needed to ignite the propellant packed within the shell casing. Composed of a metallic cup, anvil, and a small amount of impact-sensitive explosive material, the primer’s design is a testament to the meticulous attention to detail that goes into ammunition manufacturing.

Upon the pull of a shotgun’s trigger, the firing pin strikes the primer with precise force, causing the explosive material to detonate. This detonation, albeit minuscule, generates a flame that passes through the flash hole and into the main powder charge. It is this momentary flame that sets off the main event—the burning of the propellant.

Transitioning from the primer’s role, it’s important to understand the propellant that fills the body of the shell. Typically composed of smokeless powder, the propellant’s job is to convert the chemical energy stored within its grains into the kinetic energy that will propel the shot or slug forward. The quality and quantity of the propellant are meticulously calculated to provide a consistent burn rate, ensuring a steady buildup of pressure that will effectively launch the payload without damaging the firearm.

The payload, seated above the propellant, is what most people associate with shotgun shells. It can consist of a single slug or numerous pellets known as shot, and it is encased within a plastic wad that acts as a gas seal and a cushion during firing. The wad’s design is crucial as it prevents the gas from bypassing the shot and maintains the integrity of the pellets’ formation as they travel down the barrel.

Finally, the entire assembly is held together by the shell casing, typically made of plastic with a brass head, which houses the primer. The casing is not just a container; it is engineered to withstand the pressures of firing and to ensure smooth chambering and ejection from the shotgun.

Understanding the role of primers in shotgun shells reveals the complexity behind what may seem like a simple process. The primer’s reliability is paramount, as any failure at this initial stage can result in a misfire or a hangfire, compromising the shooter’s safety and performance. Manufacturers invest heavily in research and development to ensure that primers are sensitive enough to ignite under the strike of a firing pin, yet stable enough to handle transportation and storage without risk.

In conclusion, the primer may be a small component of the shotgun shell, but its role is anything but minor. It is the catalyst that ignites the propellant, setting off a sequence of events that culminates in the delivery of the payload to its intended destination. The interplay between the primer, propellant, wad, payload, and casing is a symphony of precision engineering, each playing its part to create the powerful and effective tool that is the shotgun shell. As we delve deeper into the world of firearms, it becomes clear that even the smallest components can have a profound impact on the overall performance and safety of these complex machines.

Wads and Their Impact on Shotgun Performance

The Comprehensive Guide to Shotgun Shell Components

When it comes to understanding the intricacies of shotgun performance, one cannot overlook the significance of shotgun shell components. Among these, the wad plays a pivotal role, often undervalued by those unfamiliar with the technical aspects of shotgun shooting. The wad is the unsung hero of the shotgun shell, serving multiple functions that are crucial to both the safety and effectiveness of the shotgun’s operation.

To begin with, the wad is a plastic or fiber insert that sits between the powder and the shot within a shotgun shell. Its primary function is to seal the gases produced by the ignited powder, ensuring that they do not bypass the shot and decrease the velocity. This seal is vital for maintaining consistent pressure and velocity, which are key factors in achieving a predictable shot pattern. Moreover, the wad acts as a protective barrier, preventing the delicate shot pellets from becoming deformed by the explosive force of the burning powder. Deformed pellets can lead to erratic flight paths, resulting in a less accurate shot.

Transitioning from its protective role, the wad also plays a part in the shot’s trajectory. Upon firing, the wad accompanies the shot down the barrel and out of the muzzle. Advanced wad designs feature aerodynamic considerations that can influence how the wad separates from the shot. This separation is critical because an improper release can disrupt the shot pattern. Manufacturers have developed various wad designs, such as those with petals that peel back and away from the shot, to minimize interference with the pellets as they make their way to the target.

Furthermore, the wad’s influence extends to the shooter’s experience. Recoil, the backward force felt when firing a shotgun, can be mitigated by the wad’s cushioning effect. Some wads are specifically designed to absorb a portion of the energy from the firing process, providing a more comfortable shooting experience. This is particularly beneficial for those who engage in shooting sports that require firing numerous rounds over a short period, as it can reduce shooter fatigue and improve overall performance.

The environmental impact of wads is another consideration that has gained attention in recent years. Traditional plastic wads can pose a problem when they litter natural habitats, as they do not readily decompose. In response, manufacturers have developed biodegradable wads that break down more easily in the environment, addressing the concerns of conservationists and eco-conscious shooters alike.

In conclusion, the wad is a component of shotgun shells that significantly impacts shotgun performance. From ensuring a tight gas seal and protecting the shot during ignition to influencing shot patterns and reducing recoil, the wad’s role is multifaceted. As shooting technology advances, so too do the designs and materials of wads, with ongoing innovations aimed at enhancing the shooting experience while also considering environmental sustainability. For anyone looking to optimize their shotgun’s performance or simply gain a deeper understanding of the mechanics behind their firearm, a closer examination of the humble wad is both enlightening and essential.

Exploring the Different Types of Shotgun Shell Propellants

The Comprehensive Guide to Shotgun Shell Components

When it comes to the world of shotguns, the ammunition used is as crucial as the firearm itself. Shotgun shells are complex assemblies, each component carefully designed to deliver a specific performance. Among these components, the propellant plays a pivotal role in the functionality of the shell. Understanding the different types of shotgun shell propellants is essential for any enthusiast looking to delve deeper into the technical aspects of their sport or profession.

Traditionally, black powder was the original propellant used in shotgun shells, known for its simplicity and historical significance. However, black powder has largely been replaced by smokeless powders due to their superior energy, cleaner burn, and reduced fouling of the barrel. Smokeless powders come in various forms, each with unique properties that affect the performance of the shotgun shell.

The most common type of smokeless powder used in shotgun shells is the single-base powder, which is primarily composed of nitrocellulose. This type of powder is favored for its stable burn rate and consistent performance across a range of temperatures and conditions. Single-base powders are versatile and can be found in a variety of grain shapes, including flake, ball, and extruded forms. The shape of the powder grains influences the burn rate, with smaller grains typically igniting and burning faster than larger ones.

Transitioning from single-base powders, we encounter double-base powders, which contain both nitrocellulose and nitroglycerin. The addition of nitroglycerin increases the energy content of the powder, resulting in a more powerful propellant. Double-base powders are often used in high-performance shotgun shells where additional power is needed, such as in law enforcement or competitive shooting. However, this increased power comes with a trade-off, as double-base powders can produce more recoil and may lead to increased wear on the firearm over time.

Another aspect to consider when exploring shotgun shell propellants is the burn rate. The burn rate is a critical factor that determines how quickly the powder converts into gas and builds pressure to propel the shot. Fast-burning powders are typically used in shotgun shells designed for short-range targets, where a quick burst of energy is needed to get the shot to the target rapidly. Conversely, slower-burning powders are preferred for longer-range shooting, where a sustained push is more beneficial for maintaining velocity over distance.

Moreover, the choice of propellant can also affect the perceived recoil experienced by the shooter. Faster-burning powders tend to create a sharper recoil, while slower-burning powders result in a more gradual push against the shoulder. This is an important consideration for shooters who are sensitive to recoil or who may be engaging in activities that require numerous shots over a short period, such as in clay pigeon shooting.

In conclusion, the propellant is a key component in the anatomy of a shotgun shell, with each type offering distinct advantages and considerations. Whether you’re a casual shooter or a seasoned professional, understanding the nuances of single-base and double-base powders, as well as the implications of burn rate and recoil, can help you make informed decisions about your ammunition. By selecting the appropriate propellant for your specific needs, you can optimize your shotgun’s performance and enhance your overall shooting experience. As with any technical endeavor, knowledge is power, and in the realm of shotgun shell propellants, it’s the power to hit your target with precision and confidence.

Shot Types and Sizes: Selecting the Right Payload for Your Purpose

The Comprehensive Guide to Shotgun Shell Components

When it comes to shotgun shooting, whether for sport, hunting, or defense, understanding the various shot types and sizes is crucial for selecting the right payload for your purpose. The world of shotgun shells can be complex, but with a bit of knowledge, you can make informed decisions that will enhance your shooting experience.

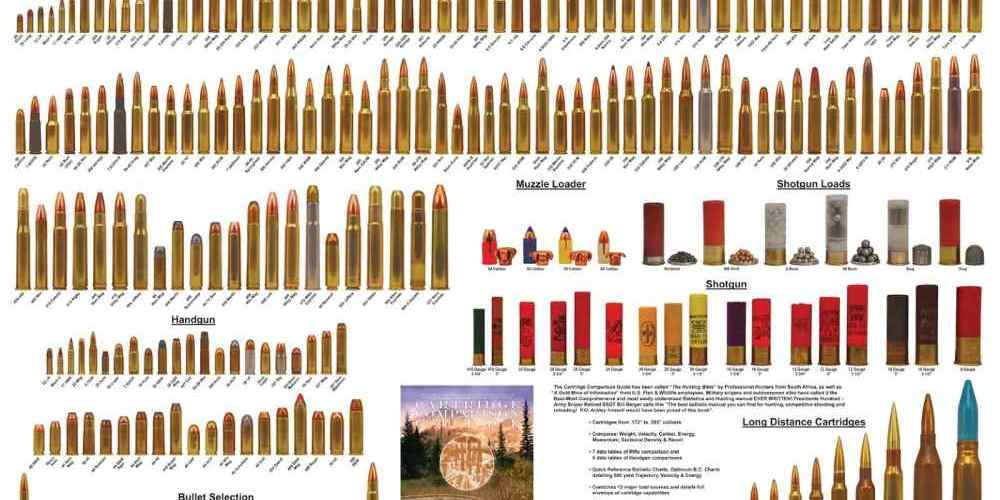

At the heart of shotgun shell selection is the concept of the payload, which refers to the type and amount of shot contained within the shell. Shot can range from tiny pellets to large slugs, and each serves a distinct purpose. The most common types of shot are birdshot, buckshot, and slugs, and each has its own set of characteristics that make it suitable for different applications.

Birdshot, as the name suggests, is typically used for hunting birds and small game. It consists of numerous small pellets that spread out in a wide pattern upon firing. This increases the likelihood of hitting a fast-moving target. The size of birdshot is categorized by numbers, with the higher numbers indicating smaller pellets. For instance, sizes can range from #9 (very small pellets) to #1 (larger pellets), with each size serving a specific hunting or target shooting need.

Transitioning to larger game, buckshot is the go-to choice. It contains fewer but larger pellets than birdshot, delivering more energy upon impact. This makes it ideal for hunting medium-sized game such as deer. Buckshot sizes are denoted by numbers and “ought” sizes, with 00 (“double-aught”) being one of the most popular for its balance of pellet size and count. The choice of buckshot size depends on the desired balance between pellet penetration and pattern spread.

For those seeking precision and power, the shotgun slug is the pinnacle. Unlike birdshot or buckshot, a slug is a single, large projectile that delivers a tremendous amount of force to a target. Slugs are used for hunting larger game at greater distances where accuracy is paramount. They are also commonly used in law enforcement and for home defense due to their stopping power and reduced risk of over-penetration compared to smaller pellets.

The size of the shot is not the only consideration; the length of the shotgun shell also plays a role in performance. Common lengths include 2 ¾ inches, 3 inches, and 3 ½ inches, with the longer shells capable of holding more shot or a larger slug, thus delivering a more powerful charge. However, it’s essential to ensure that your shotgun is chambered for the length of shell you intend to use.

In addition to size and type, the material of the shot is another factor to consider. Lead has traditionally been the material of choice due to its density and malleability, which allow for effective patterning and energy transfer. However, due to environmental concerns, non-toxic alternatives such as steel, bismuth, and tungsten are becoming more prevalent, especially in areas where lead shot is restricted or banned.

Ultimately, the selection of shotgun shell components is a balance between the intended use, the performance characteristics of the shot, and the capabilities of your shotgun. By understanding the nuances of shot types and sizes, you can tailor your ammunition choice to your specific needs, ensuring a successful and satisfying shooting experience. Whether you’re aiming for precision or power, there’s a shotgun shell that’s perfectly suited for your purpose.