“Keep Your AR15 Battle-Ready: Upgrade with Precision, Replace with Confidence.”

Identifying Common Signs of Wear in AR15 Components

Maintaining Reliability: Replacing Worn AR15 Components

The AR15 is a popular firearm known for its modularity and reliability. However, like any mechanical device, it is subject to wear and tear over time. Identifying common signs of wear in AR15 components is crucial for maintaining the firearm’s reliability and ensuring safe operation. In this article, we’ll explore how to recognize when parts need replacing and the importance of regular maintenance.

Firstly, let’s consider the bolt carrier group (BCG), which is the heart of the AR15. It is responsible for the firearm’s cycling process and is subjected to significant stress with each shot. One of the telltale signs of wear in the BCG is visible on the bolt itself. Look for any cracks or fractures, especially around the bolt lugs and the cam pin hole. If these areas show signs of excessive wear or damage, it’s time to replace the bolt. Additionally, the gas rings on the bolt should be checked for resilience. A simple test is to stand the bolt on its end; if it collapses under its own weight, the gas rings may need replacing.

Moving on to the barrel, accuracy can be a strong indicator of its condition. As the barrel wears, particularly the throat area just ahead of the chamber, you may notice a decrease in accuracy. This is due to the increased space allowing more gas to escape before the bullet exits the barrel, affecting the bullet’s velocity and stability. To check for wear, use a bore scope or have a gunsmith inspect the rifling near the chamber. If the rifling appears eroded or smoothed out, it’s likely time for a barrel replacement.

The trigger group is another component that can show signs of wear. A gritty or inconsistent trigger pull can indicate that the sear or hammer has worn down. This can affect the crispness and predictability of the trigger, which is essential for accurate shooting. Inspecting these parts for any unusual wear patterns or pitting can help determine if they need to be replaced.

Furthermore, the buffer and buffer spring, which help mitigate recoil and manage the cycling of rounds, can also wear out. A buffer that shows significant pitting or a spring that has lost its tension can lead to malfunctions. To assess the buffer spring, compare its length to a new one; if it’s significantly shorter, it’s time for a replacement.

The feed ramps, which guide the rounds from the magazine into the chamber, should not be overlooked. Worn or damaged feed ramps can cause feeding issues, leading to jams and reliability problems. Inspect these for any gouges or uneven wear that could impede the smooth feeding of rounds.

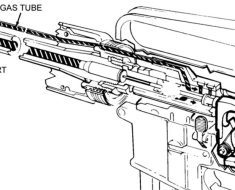

Lastly, the gas system, including the gas block and gas tube, is vital for the rifle’s cycling action. Carbon buildup and erosion can cause gas leaks, which may result in cycling issues. Regular cleaning can prevent some wear, but if the gas block or tube is damaged, they will need to be replaced to maintain proper function.

In conclusion, maintaining the reliability of your AR15 requires vigilance and an understanding of the common signs of wear. Regular inspections and maintenance can prevent small issues from becoming major problems. By replacing worn components promptly, you ensure that your AR15 remains a dependable tool for sport, defense, or duty. Remember, a well-maintained firearm is not only more reliable but also safer to operate. Stay proactive in your maintenance routine, and your AR15 will serve you well for years to come.

The Importance of Regular Maintenance for AR15 Reliability

Maintaining Reliability: Replacing Worn AR15 Components

The AR15 is a popular firearm known for its versatility and reliability. However, like any mechanical device, it requires regular maintenance to function at its best. Ensuring the reliability of your AR15 involves more than just cleaning; it also means being vigilant about replacing worn components before they fail. This proactive approach to maintenance can prevent malfunctions and extend the life of your firearm.

Firstly, it’s essential to understand that the AR15 is a system of parts working in harmony. When one component wears down, it can affect the performance of the entire rifle. For instance, a worn bolt or bolt carrier group (BCG) can lead to failures to feed, eject, or fire. These are critical components that handle the stress of cycling with each shot. Over time, the gas rings on the bolt can wear out, and the bolt’s locking lugs can become worn or damaged. Regular inspection of these parts for signs of wear or fatigue is crucial. If you notice any cracks, deformation, or excessive wear, it’s time to replace these components to maintain the rifle’s reliability.

Another key area to monitor is the buffer and buffer spring. These parts mitigate recoil and help return the bolt into battery after firing. A weak or worn buffer spring can result in a sluggish return to battery, which may cause malfunctions. Similarly, if the buffer itself is damaged, it can affect the cycling of the rifle. Replacing these parts before they become problematic is a small investment in ensuring your AR15 continues to operate smoothly.

The trigger assembly is also prone to wear, especially if you shoot frequently. A worn trigger can lead to a gritty pull or inconsistent performance, which can affect accuracy and reliability. Upgrading to a high-quality trigger can not only improve the feel and response but also contribute to the overall longevity of your rifle.

Furthermore, the barrel is a critical component that can wear out over time, especially with high round counts. A worn barrel can lead to decreased accuracy and, in extreme cases, safety issues. Pay attention to the condition of the rifling and the throat of the barrel. If you start to see a decline in accuracy or signs of erosion, consider replacing the barrel to restore the rifle’s performance.

The importance of maintaining magazines is often overlooked. Magazines are frequently dropped, stepped on, and subjected to harsh conditions. Worn magazine springs and followers can cause feeding issues, which can be mistaken for a problem with the rifle itself. Regularly rotating and inspecting your magazines, and replacing worn components, can prevent these issues.

Lastly, don’t forget about the smaller parts like the extractor and ejector. These parts are under constant stress and can wear out or break. Keeping spare parts on hand and replacing them when they show signs of wear can save you from unexpected malfunctions during shooting sessions or competitions.

In conclusion, maintaining the reliability of your AR15 requires a technical understanding of its components and a commitment to regular maintenance. By replacing worn parts proactively, you can prevent malfunctions and ensure that your rifle is ready to perform when you need it most. Remember, a well-maintained AR15 is not only more reliable but also safer to operate. So, take the time to inspect your rifle regularly, and don’t hesitate to replace parts that are showing their age. Your diligence will pay off in the form of a dependable and long-lasting firearm.

Step-by-Step Guide to Replacing Your AR15’s Worn-Out Parts

Maintaining Reliability: Replacing Worn AR15 Components

The AR15 is a popular firearm known for its versatility and reliability. However, like any mechanical device, it requires regular maintenance and occasional part replacements to ensure it functions correctly. Over time, components can wear out, potentially compromising the rifle’s performance. To maintain the reliability of your AR15, it’s essential to recognize when parts need replacing and understand how to do so safely and effectively.

Firstly, it’s crucial to identify the signs of wear. Look for any visible damage, such as cracks or deformations, on parts like the bolt carrier group, gas rings, or the buffer and buffer spring. Additionally, pay attention to the performance of your rifle. If you notice issues such as frequent jams, inconsistent cycling, or a change in recoil pattern, these could be indicators that certain parts are due for replacement.

Once you’ve determined which components need attention, ensure you have the right tools and replacement parts on hand. A typical AR15 armorer’s toolkit should include items like a set of punches, a hammer, a receiver block, and a torque wrench. Quality replacement parts are crucial for maintaining the integrity of your firearm, so opt for reputable brands and avoid cutting corners with cheaper, lower-quality components.

Before you begin the replacement process, always practice safety by verifying that your firearm is unloaded. Remove the magazine, clear the chamber, and double-check to ensure there are no rounds present. Once you’ve confirmed the rifle is safe to handle, you can proceed with disassembly.

Starting with the bolt carrier group, push out the retaining pin and remove the firing pin. Next, take out the bolt cam pin and the bolt itself. Inspect these parts for wear and replace them if necessary. When reassembling, apply a light coat of gun oil to reduce friction and protect against corrosion.

The gas rings on the bolt are another common wear item. If they’re worn, your rifle may have cycling issues. To test their condition, stand the bolt on its head. If it collapses under its own weight, the gas rings need replacing. Install new rings by spiraling them onto the bolt, ensuring the gaps are staggered to maintain a proper gas seal.

Moving on to the buffer system, remove the buffer and spring from the buffer tube. Inspect the buffer for any dents and the spring for signs of fatigue or kinks. Replace these parts if they show significant wear. When reinserting the spring and buffer, ensure they’re seated correctly to avoid any cycling issues.

Lastly, consider the condition of your trigger assembly. Over time, trigger components can wear down, leading to a less crisp pull and potentially affecting accuracy. If you’re not comfortable working on the trigger yourself, this is a task best left to a qualified gunsmith.

After replacing any worn parts, reassemble your AR15 and perform a function check. This includes verifying the safety selector works, the trigger resets properly, and the bolt locks back on an empty magazine. If everything checks out, take your rifle to the range for a test fire. This will allow you to confirm that all replaced components are working harmoniously and that your AR15 is back to its reliable self.

In conclusion, keeping your AR15 in top condition requires vigilance and a proactive approach to maintenance. By replacing worn components in a timely manner, you’ll ensure your rifle remains a dependable tool for whatever purpose you require, be it competition, hunting, or defense. Remember, a well-maintained AR15 is not just a pleasure to shoot; it’s also a testament to the owner’s commitment to responsible firearm stewardship.

Top AR15 Components to Inspect and Replace for Optimal Performance

Maintaining Reliability: Replacing Worn AR15 Components

The AR15 is a versatile and widely used rifle, cherished by enthusiasts and professionals alike for its modularity and reliability. However, like any mechanical device, it requires regular maintenance to ensure optimal performance. Over time, components can wear down, affecting the rifle’s functionality. To maintain the AR15’s reliability, it’s crucial to inspect and replace parts that are prone to wear and tear.

One of the first components to check is the bolt carrier group (BCG), which is the heart of the AR15’s operation. The BCG endures significant stress with each round fired, making it susceptible to wear. Pay particular attention to the bolt itself, especially the bolt lugs and the gas rings. If the lugs show signs of cracking or if the gas rings have lost their tension, it’s time to replace them. A worn bolt can lead to failures to lock, while compromised gas rings can cause cycling issues.

The buffer and buffer spring, which absorb recoil and help cycle the rifle, are also subject to wear. After thousands of rounds, the spring can weaken, and the buffer can show signs of damage. A weak spring may result in a sluggish return to battery, and a damaged buffer can affect the rifle’s overall cycling. Replacing these components is a relatively simple task that can restore the smooth operation of your AR15.

Another critical area to monitor is the fire control group, which includes the trigger, hammer, disconnector, and their associated springs. These parts work in concert to ensure a crisp trigger pull and reliable ignition. Over time, springs can lose their strength, and contact surfaces can wear down, leading to a mushy trigger feel or light primer strikes. Upgrading to a new fire control group can not only improve reliability but also enhance the shooting experience with a cleaner break and reset.

The barrel is the soul of the rifle, and its condition is paramount to accuracy and reliability. Throat erosion and general wear from high round counts can diminish accuracy and, in extreme cases, lead to malfunctions. Inspecting the barrel for signs of wear, such as pitting or changes in the rifling, can help determine if it’s time for a replacement. A fresh barrel will ensure that the rifle maintains its ballistic performance and accuracy.

Lastly, don’t overlook the importance of smaller components such as the extractor and ejector. These parts ensure that spent casings are reliably removed from the chamber and ejected from the rifle. A worn extractor can lead to failures to extract, while a faulty ejector can cause stovepipes or other ejection issues. Replacing these parts is often straightforward and can prevent frustrating malfunctions during shooting sessions.

In conclusion, maintaining the reliability of your AR15 involves regular inspection and timely replacement of key components. By keeping an eye on the bolt carrier group, buffer system, fire control group, barrel, and extraction/ejection hardware, you can ensure that your rifle functions smoothly and dependably. Remember, the longevity and performance of your AR15 are directly linked to the care and attention you give to its maintenance. With a technical understanding and a friendly approach to routine upkeep, your AR15 will continue to be a reliable companion at the range or in the field for years to come.

How to Choose Quality Replacement Parts for Your AR15

Maintaining Reliability: Replacing Worn AR15 Components

The AR15 is a versatile and widely used rifle, cherished by enthusiasts for its modularity and ease of customization. However, like any mechanical device, it is subject to wear and tear over time. Ensuring the reliability of your AR15 involves regular maintenance and the timely replacement of worn components. When it comes to choosing quality replacement parts, there are several factors to consider to keep your rifle in top condition.

Firstly, it’s essential to understand the importance of material quality. High-grade materials such as aircraft-grade aluminum, high-carbon steel, or titanium offer durability and longevity. For instance, when replacing critical components like the bolt carrier group (BCG), opting for parts made from these materials can significantly enhance performance. The BCG is the heart of the AR15, and a premium-grade steel BCG with a protective coating such as nickel boron or phosphate can resist corrosion and reduce friction, leading to a smoother action and extended lifespan.

Another critical aspect is the manufacturing process. Parts that are precision-machined to tight tolerances ensure a better fit and function within your AR15. This precision reduces the likelihood of malfunctions and improves overall accuracy. It’s advisable to seek out components from reputable manufacturers who adhere to stringent quality control standards. These companies often employ advanced techniques like Computer Numerical Control (CNC) machining, which results in parts that meet or exceed military specifications.

Compatibility is also a key consideration when selecting replacement parts for your AR15. With the rifle’s modular design, it’s tempting to mix and match components from various manufacturers. However, not all parts are created equal, and some may not work seamlessly with others. It’s crucial to verify that the replacement parts are compatible with your specific AR15 model and configuration. This ensures that you maintain the rifle’s functionality and avoid potential safety issues.

Furthermore, consider the part’s intended use and the conditions it will be subjected to. For example, if you frequently shoot in adverse weather conditions, you might want to invest in parts with enhanced corrosion resistance. Similarly, if you use your AR15 for competitive shooting, you might prioritize parts that offer a competitive edge, such as a lighter, adjustable trigger for a crisper pull and faster reset.

When it comes to installation, even the highest quality replacement parts can underperform if not installed correctly. While many AR15 owners enjoy working on their rifles, it’s important to recognize your limits. If you’re not confident in your ability to replace a particular component, it’s wise to seek the assistance of a professional gunsmith. This ensures that the part is installed correctly and safely, maintaining the integrity and reliability of your firearm.

Lastly, don’t overlook the value of customer reviews and community feedback. The AR15 community is active and vocal, and many shooters share their experiences with different parts and manufacturers. Reading reviews and participating in forums can provide insights into the real-world performance of replacement parts, helping you make an informed decision.

In conclusion, choosing quality replacement parts for your AR15 is a multifaceted process that involves considering material quality, manufacturing precision, compatibility, intended use, and community feedback. By taking these factors into account, you can ensure that your rifle remains reliable, accurate, and ready for whatever challenges you may face. Remember, the right parts not only extend the life of your AR15 but also enhance your shooting experience.