Top Mistakes to Avoid When Reloading Ammunition

Reloading ammunition is a popular and rewarding hobby among shooting enthusiasts, hunters, and competitive shooters alike. It offers the benefits of cost savings, customization, and the satisfaction of crafting your own rounds. However, reloading is a precise and potentially hazardous activity that requires attention to detail and adherence to safety protocols. Mistakes in the process can lead to dangerous malfunctions, damage to firearms, or even serious injury.

This article delves into the most common mistakes made during ammunition reloading, providing insights, examples, and practical tips for both beginners and seasoned reloaders to avoid these pitfalls. By understanding these errors, reloaders can enhance safety, improve cartridge performance, and enjoy their hobby with greater confidence.

Understanding the Importance of Proper Reloading Practices

Before exploring specific mistakes, it’s essential to understand why meticulous reloading practices matter. Unlike factory ammunition manufacturing, handloading involves manual steps that require accuracy. Each component—cases, primers, powder charges, and bullets—must be measured and assembled correctly. Even minor deviations can cause pressure spikes or unreliable performance.

According to a 2019 survey by the National Shooting Sports Foundation (NSSF), approximately 7 million Americans reload their own ammunition. With such a large community involved in this activity, education about common errors is vital for promoting safety.

Mistake #1: Using Incorrect or Unverified Reloading Data

One of the most frequent errors reloaders make is relying on inaccurate or outdated load data. Load data refers to the published guidelines from powder manufacturers or reloading manuals that specify safe powder charges, bullet weights, seating depths, and pressures for various cartridges.

- Why It’s Dangerous: Using incorrect data can result in excessive pressures that might cause catastrophic firearm failure.

- Example: In 2015, an experienced reloader shared his story on a popular online forum where he mistakenly used a high powder charge intended for a magnum cartridge in a standard load. The resulting overpressure caused his rifle’s barrel to bulge after firing just a few rounds.

Best Practices:

- Always use reputable sources such as Hodgdon’s Reloading Data Center or Hornady’s manuals.

- Cross-reference load data when trying new powders or bullet types.

- Avoid experimenting with loads outside published guidelines unless you have extensive experience and proper equipment like pressure testing tools.

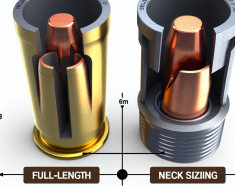

Mistake #2: Neglecting Case Inspection and Preparation

The brass casing is the foundation of every round of ammunition. Neglecting thorough inspection and preparation of cases can lead to dangerous situations such as case ruptures or misfires.

- Common Oversights Include:

- Failing to check for cracks, splits, or signs of excessive wear.

- Not cleaning primer pockets which can cause improper primer seating.

- Ignoring case length variations which may affect chambering and pressure.

Case Study:

A competitive shooter reported inconsistent accuracy during matches only to discover several cases had hairline cracks near the neck area caused by repeated firing without adequate inspection. Replacing these cases improved both safety and shot grouping significantly.

Recommendations:

- Use visual inspection combined with tools like case gauges or calipers.

- Trim cases that exceed recommended lengths using case trimmers.

- Clean primer pockets thoroughly with dedicated tools before priming.

Mistake #3: Improper Primer Handling and Seating

The primer ignites the powder charge inside the cartridge; therefore, its correct handling is critical. Primers are sensitive components that require careful treatment during installation.

- Dangers of Improper Primer Handling:

- Poorly seated primers can cause misfires or delayed ignition (hangfires).

- Denting primers too deeply may result in slam-fires — unintentional discharge upon chambering.

- Using incorrect primer types for specific cartridges affects performance adversely.

Example:

An anecdote from a novice reloader highlights how attempting to seat primers with excessive force led to dented primers that caused several misfires during target practice sessions. After switching to a reliable priming tool with adjustable seating depth control, reliability improved dramatically.

Tips for Safe Primer Use:

- Select primers compatible with your cartridge specifications (small rifle vs. large rifle primers).

- Avoid “hand seating” primers; always use dedicated priming tools designed for consistent depth control.

- Store primers in cool dry conditions away from impact risks; dispose of damaged primers responsibly.

Mistake #4: Incorrect Powder Measurement and Charging

The powder charge directly influences the velocity and pressure generated within a cartridge when fired. Incorrect measurement or charging is one of the leading causes of accidents in handloading operations.

- Mistakes include: