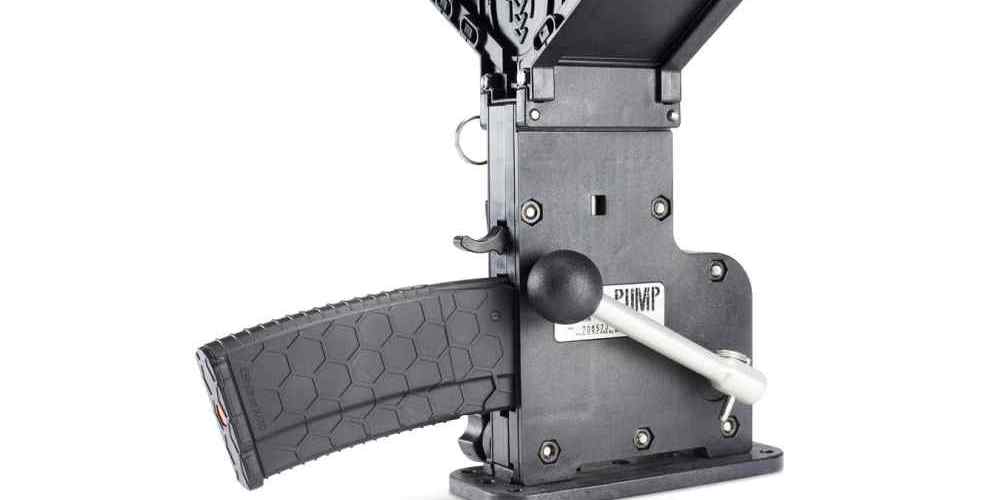

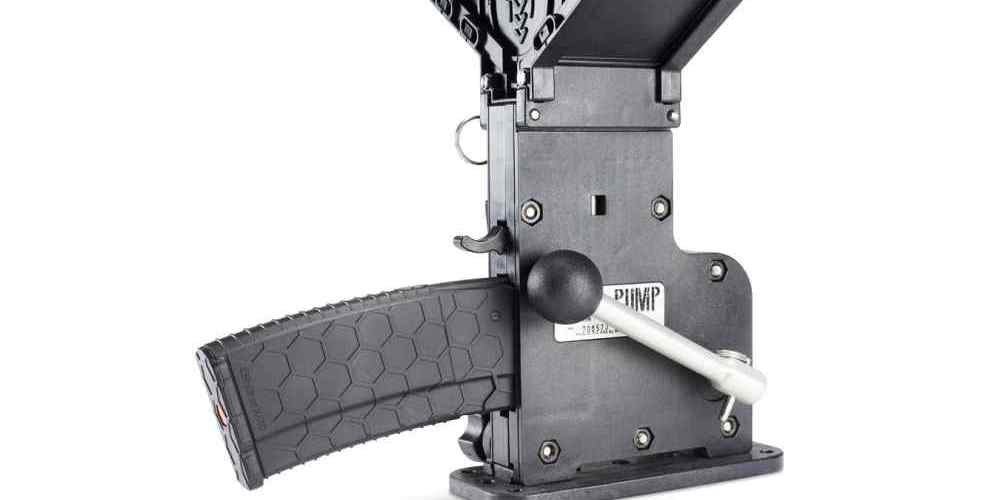

“AR15 magazines: high firepower, high environmental cost.”

Deforestation

The production of AR15 magazines has a significant environmental impact, particularly in terms of deforestation. The process of manufacturing these magazines requires the use of various materials, including wood, which often leads to the destruction of forests. This deforestation not only contributes to habitat loss for countless species of plants and animals but also has a negative impact on the overall health of our planet.

When trees are cut down to make way for the production of AR15 magazines, it disrupts the delicate balance of ecosystems. Forests play a crucial role in regulating the Earth’s climate by absorbing carbon dioxide from the atmosphere. When trees are removed, this natural process is disrupted, leading to an increase in greenhouse gas emissions and contributing to global warming.

In addition to the environmental impact of deforestation, the production of AR15 magazines also has a direct impact on the quality of our air and water. The manufacturing process often involves the use of chemicals and other pollutants that can contaminate the air and water supply, leading to a host of health problems for both humans and wildlife.

Furthermore, the transportation of materials and finished products also contributes to carbon emissions, further exacerbating the environmental impact of AR15 magazine production. The use of fossil fuels in transportation adds to the overall carbon footprint of these magazines, making them even more harmful to the environment.

It is important to consider the environmental impact of the products we use and consume on a daily basis. By being mindful of the resources and materials that go into the production of items like AR15 magazines, we can make more informed choices that have a positive impact on the planet.

One way to mitigate the environmental impact of AR15 magazine production is to opt for alternative materials that are more sustainable and eco-friendly. For example, manufacturers could explore the use of recycled materials or plant-based alternatives that have a lower impact on the environment.

Another way to reduce the environmental impact of AR15 magazine production is to support companies that prioritize sustainability and environmental stewardship in their manufacturing processes. By choosing products from companies that are committed to reducing their carbon footprint and minimizing their impact on the environment, consumers can help drive positive change in the industry.

In conclusion, the production of AR15 magazines has a significant environmental impact, particularly in terms of deforestation. By being mindful of the resources and materials that go into the production of these magazines, we can make more informed choices that have a positive impact on the planet. It is important to consider the environmental consequences of the products we use and consume and to support companies that prioritize sustainability and environmental stewardship in their manufacturing processes. Together, we can work towards a more sustainable future for our planet.

Water Pollution

The production of AR15 magazines has a significant environmental impact, particularly in terms of water pollution. The manufacturing process of these magazines involves the use of various chemicals and materials that can potentially contaminate water sources if not properly managed.

One of the primary concerns with AR15 magazine production is the use of metal plating processes. These processes often involve the use of toxic chemicals such as chromium, nickel, and cadmium, which can leach into water sources if not properly treated. Additionally, the wastewater generated from these processes can contain heavy metals and other pollutants that can harm aquatic ecosystems and human health.

In addition to metal plating processes, the production of AR15 magazines also involves the use of plastics and other materials that can contribute to water pollution. Plastic pellets and other raw materials used in the manufacturing process can be inadvertently released into water sources, leading to pollution and potential harm to aquatic life.

Furthermore, the energy-intensive nature of AR15 magazine production can also contribute to water pollution. The extraction and processing of raw materials, as well as the transportation of finished products, can result in the release of greenhouse gases and other pollutants that can ultimately impact water quality.

To mitigate the environmental impact of AR15 magazine production on water sources, manufacturers can take several steps to reduce pollution. Implementing water recycling and treatment systems can help minimize the release of contaminants into water sources. Additionally, using alternative materials and production processes that are less harmful to the environment can also help reduce water pollution.

Regulatory agencies can also play a role in ensuring that AR15 magazine manufacturers comply with environmental regulations and standards to protect water quality. By enforcing strict pollution control measures and monitoring compliance, regulators can help minimize the impact of magazine production on water sources.

Ultimately, addressing the environmental impact of AR15 magazine production requires a collaborative effort between manufacturers, regulators, and consumers. By implementing sustainable practices and investing in pollution control measures, the industry can help protect water quality and preserve aquatic ecosystems for future generations.

In conclusion, the production of AR15 magazines has a significant environmental impact, particularly in terms of water pollution. By addressing the use of toxic chemicals, implementing water recycling systems, and complying with environmental regulations, manufacturers can help minimize the impact of magazine production on water quality. It is essential for all stakeholders to work together to protect water sources and ensure a sustainable future for our planet.

Energy Consumption

The production of AR15 magazines has a significant environmental impact, particularly in terms of energy consumption. The manufacturing process of these magazines requires a substantial amount of energy, from the extraction of raw materials to the final assembly of the product. Understanding the energy consumption involved in the production of AR15 magazines is crucial in assessing the overall environmental footprint of these products.

One of the primary sources of energy consumption in the production of AR15 magazines is the extraction and processing of raw materials. The materials used in the manufacturing of these magazines, such as aluminum and steel, require a considerable amount of energy to extract from the earth and refine into usable forms. The mining and processing of these materials contribute to greenhouse gas emissions and other environmental impacts, further exacerbating the energy consumption associated with AR15 magazine production.

In addition to the energy required for raw material extraction, the manufacturing process itself also consumes a significant amount of energy. The machining, shaping, and assembly of AR15 magazines all require electricity and other forms of energy to operate the machinery and equipment involved in the production process. The use of energy-intensive processes in manufacturing contributes to the overall energy consumption associated with AR15 magazine production.

Furthermore, transportation plays a crucial role in the energy consumption of AR15 magazine production. The transportation of raw materials to manufacturing facilities, as well as the distribution of finished products to retailers and consumers, requires energy in the form of fuel for trucks, ships, and other modes of transportation. The reliance on fossil fuels for transportation contributes to greenhouse gas emissions and other environmental impacts, further adding to the energy consumption associated with AR15 magazine production.

Overall, the energy consumption involved in the production of AR15 magazines has a significant environmental impact. The extraction and processing of raw materials, the manufacturing process itself, and the transportation of materials and products all contribute to the overall energy consumption associated with these products. Understanding the energy consumption of AR15 magazine production is essential in assessing the environmental footprint of these products and identifying opportunities for improvement.

In conclusion, the production of AR15 magazines has a substantial environmental impact, particularly in terms of energy consumption. The extraction and processing of raw materials, the manufacturing process, and transportation all contribute to the overall energy consumption associated with these products. By understanding the energy consumption involved in the production of AR15 magazines, we can work towards reducing the environmental impact of these products and moving towards more sustainable manufacturing practices.

Waste Generation

The production of AR15 magazines has a significant environmental impact, particularly in terms of waste generation. From the extraction of raw materials to the manufacturing process and eventual disposal, each step in the production cycle contributes to the accumulation of waste that can harm the environment.

One of the primary sources of waste in AR15 magazine production is the extraction of raw materials. The production of metal magazines, for example, requires the mining of metals such as aluminum and steel. This process generates a significant amount of waste, including tailings, which are the byproducts of mining operations. These tailings can contain harmful chemicals and heavy metals that can leach into the soil and water, contaminating the environment.

Once the raw materials have been extracted, they must be processed and manufactured into AR15 magazines. This process also generates waste, including scrap metal, excess material, and wastewater. Scrap metal and excess material are often discarded as waste, contributing to landfill accumulation. Wastewater from manufacturing processes can contain pollutants such as heavy metals, oils, and solvents, which can contaminate water sources if not properly treated.

In addition to waste generated during production, AR15 magazines also contribute to waste generation during their use and eventual disposal. Magazines are often made of non-biodegradable materials such as plastic and metal, which can take hundreds of years to decompose in a landfill. When magazines reach the end of their lifespan, they are often discarded and can end up in landfills, further contributing to waste accumulation.

To mitigate the environmental impact of AR15 magazine production, manufacturers can take steps to reduce waste generation throughout the production cycle. This can include implementing recycling programs to reuse scrap metal and excess material, as well as treating wastewater to remove pollutants before it is discharged into the environment. Manufacturers can also explore alternative materials that are more sustainable and biodegradable, reducing the environmental impact of magazine production.

Consumers can also play a role in reducing waste generation by properly disposing of AR15 magazines at the end of their lifespan. This can include recycling metal components and disposing of plastic components in a responsible manner. Additionally, consumers can choose to purchase magazines made from sustainable materials or opt for reusable alternatives to reduce waste generation.

In conclusion, the production of AR15 magazines has a significant environmental impact in terms of waste generation. From the extraction of raw materials to the manufacturing process and eventual disposal, each step in the production cycle contributes to the accumulation of waste that can harm the environment. By taking steps to reduce waste generation throughout the production cycle and properly disposing of magazines at the end of their lifespan, manufacturers and consumers can help mitigate the environmental impact of AR15 magazine production.

Carbon Emissions

The production of AR15 magazines has a significant environmental impact, particularly in terms of carbon emissions. Carbon emissions are a major contributor to climate change, and it is important to understand how the production of these magazines contributes to this issue.

The manufacturing process of AR15 magazines involves the use of various materials, such as steel, aluminum, and plastic. These materials require energy to extract, refine, and process, which in turn leads to the release of carbon dioxide and other greenhouse gases into the atmosphere. Additionally, the transportation of these materials to the manufacturing facility also contributes to carbon emissions.

Once the materials have been processed and assembled into AR15 magazines, they must be transported to retailers and ultimately to consumers. This transportation process further adds to the carbon footprint of these products. The use of fossil fuels in trucks, ships, and planes for transportation releases even more carbon dioxide into the atmosphere.

In addition to the production and transportation of AR15 magazines, the disposal of these products also has environmental consequences. When AR15 magazines reach the end of their lifespan, they are often discarded in landfills where they can take hundreds of years to decompose. As they break down, they release methane, a potent greenhouse gas that contributes to climate change.

To mitigate the environmental impact of AR15 magazine production, manufacturers can take steps to reduce their carbon emissions. This can include using renewable energy sources in their manufacturing processes, optimizing their supply chain to reduce transportation emissions, and implementing recycling programs to reduce waste.

Consumers can also play a role in reducing the environmental impact of AR15 magazine production. By choosing to purchase magazines made from recycled materials or opting for reusable alternatives, consumers can help reduce the demand for new magazines and the carbon emissions associated with their production.

Overall, the production of AR15 magazines has a significant environmental impact in terms of carbon emissions. By understanding the lifecycle of these products and taking steps to reduce their carbon footprint, manufacturers and consumers can work together to minimize the environmental consequences of AR15 magazine production. It is important for all stakeholders to be aware of the environmental impact of their choices and to take action to protect the planet for future generations.