Reloading for Long-Range Shooting: How to Get Consistent Groups

Long-range shooting demands precision, patience, and above all, consistency. One of the most critical components in achieving tight groups at extended distances is the quality and uniformity of your ammunition. Reloading your own ammunition allows shooters to tailor loads specifically for their firearms, optimizing every variable for superior performance. This article delves into the art and science of reloading for long-range shooting, offering practical advice, proven techniques, and insights drawn from expert practices to help you achieve consistent groups downrange.

The Importance of Consistency in Long-Range Shooting

Consistency is the cornerstone of accuracy in long-range shooting. When a shooter can rely on every shot behaving predictably, they can better adjust for environmental factors such as wind, temperature, and elevation changes. Inconsistent ammunition introduces variables that complicate shot placement and reduce confidence.

Studies have shown that even minor variations in bullet velocity or seating depth can lead to significant deviations at distances beyond 500 yards. For instance, a velocity variation of just 20 feet per second (fps) can cause a vertical shift of several inches at 1000 yards. This makes controlling every aspect of your reloads essential for maintaining precision.

Understanding the Components: Bullet, Powder, Primer, and Case

Reloading begins with understanding each component’s role and how it influences consistency:

- Bullet: The bullet’s weight, shape, and construction affect its ballistic coefficient (BC), which determines how well it retains velocity over distance. Selecting bullets with high BCs—such as boat-tail or VLD designs—can improve downrange performance.

- Powder: The type and charge weight directly influence muzzle velocity and pressure. Using consistent powder charges is crucial to reducing velocity spreads between shots.

- Primer: Primers ignite the powder charge; different brands and types can affect ignition consistency. Match-grade primers are often preferred for long-range reloads due to their uniform ignition properties.

- Case: The brass case holds all components together. Case volume, neck tension, and overall condition impact internal ballistics. Proper case preparation ensures reliable chambering and ignition.

Each element must be carefully selected and matched to produce predictable results.

Step-by-Step Guide to Achieving Consistent Reloads

The process of creating consistent loads involves several key steps that require attention to detail:

1. Start With Quality Brass

Your brass cases are the foundation of every reload. Using high-quality, uniform brass reduces variability caused by differences in case volume or wall thickness.

- Case Selection: Choose brass from reputable manufacturers or once-fired cases known for consistency.

- Case Prep: Clean your cases thoroughly using a tumbler or ultrasonic cleaner to remove debris that might affect seating or ignition.

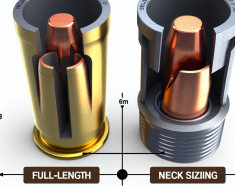

- Case Sizing: Use full-length sizing dies to ensure cases chamber smoothly but avoid excessive resizing which can shorten case life.

2. Measure Powder Charges Precisely

The powder charge weight affects both velocity and pressure. Even slight deviations can cause significant inconsistencies at long range.

- Dramatic Consistency: Use a high-quality digital scale capable of measuring powder charges within ±0.01 grains.

- Avoid Static Electricity: Static can cause powder to cling during weighing; anti-static measures like ionizers or grounded mats help maintain accuracy.

- Charge Uniformity Testing: Periodically verify charges during loading sessions rather than relying solely on initial calibration.

3. Seating Depth and Bullet Alignment

The bullet seating depth influences cartridge overall length (COL), which affects chamber pressure and barrel harmonics.

- Select Optimal Seating Depth: Use tools like a comparator gauge or bullet jump measurement devices to find the “sweet spot” where the bullet sits just off the lands for maximum accuracy.

- Bore Sighting & Testing: Test different seating depths on paper targets at known distances to observe group sizes before finalizing your load.

- Bullet Alignment Dies: Consider using specialized dies designed to align bullets perfectly concentric with the case neck to reduce runout.

4. Primer Selection and Seating

A consistent ignition source is vital for repeatable muzzle velocities.

- Select Match-Grade Primers: Brands like Federal Gold Medal Match or CCI BR-4 are favored by many long-range shooters due to their uniform performance.

- Avoid Over- or Under-Seating Primers: Primers should be seated flush with or slightly below the case head without deforming them; inconsistent primer seating depth can cause ignition variability.

5. Load Development Through Testing

No two rifles behave identically; load development is a critical phase where you fine-tune your components for peak performance with your specific firearm.

- Create Load Series: Develop multiple loads varying powder charge slightly (e.g., ±0.2 grains)