“Crafted with precision, designed for performance.”

Benefits of Precision Engineering in Firearms Manufacturing

Precision engineering plays a crucial role in the manufacturing of firearms, ensuring that each component is crafted with the utmost accuracy and attention to detail. One such component that benefits greatly from precision engineering is the AR15 trigger, a critical part of the firearm that directly impacts its performance and accuracy.

When it comes to the AR15 trigger, precision engineering is essential in ensuring that the trigger functions smoothly and reliably. A premium AR15 trigger is designed to have a crisp, clean break with minimal creep and overtravel, providing the shooter with a consistent and predictable trigger pull. This level of precision is achieved through meticulous machining and quality control processes that guarantee each trigger meets strict specifications.

One of the key benefits of precision engineering in the manufacturing of AR15 triggers is improved accuracy. A high-quality trigger with minimal play and a consistent pull weight can help shooters achieve tighter shot groups and better overall performance. By reducing the variability in trigger pull, precision-engineered triggers allow shooters to focus on their marksmanship without worrying about inconsistencies in their trigger.

In addition to improved accuracy, precision-engineered AR15 triggers also offer enhanced reliability. By ensuring that each trigger is manufactured to exacting standards, manufacturers can minimize the risk of malfunctions and ensure that the trigger will perform flawlessly in any conditions. This level of reliability is crucial for shooters who depend on their firearms for self-defense, hunting, or competitive shooting.

Another benefit of precision engineering in the manufacturing of AR15 triggers is increased durability. By using high-quality materials and advanced machining techniques, manufacturers can create triggers that are built to last. This means that shooters can rely on their triggers to withstand thousands of rounds without experiencing any wear or degradation in performance.

Furthermore, precision-engineered AR15 triggers offer a superior shooting experience. A smooth, consistent trigger pull can make a significant difference in how a firearm feels and handles, allowing shooters to enjoy a more comfortable and enjoyable shooting experience. Whether on the range or in the field, a premium AR15 trigger can enhance the overall shooting experience and help shooters perform at their best.

In conclusion, precision engineering plays a vital role in the manufacturing of AR15 triggers, ensuring that each component is crafted with the highest level of accuracy and attention to detail. By investing in a precision-engineered trigger, shooters can enjoy improved accuracy, reliability, durability, and overall shooting experience. Whether for recreational shooting, hunting, or self-defense, a premium AR15 trigger is a worthwhile investment for any firearm enthusiast.

The Importance of Quality Materials in AR15 Trigger Production

When it comes to precision engineering, every component of a firearm plays a crucial role in its overall performance. One such component that is often overlooked but is essential for accuracy and reliability is the trigger. In the world of AR15 rifles, a premium trigger can make all the difference in the shooting experience. From crisp and clean breaks to minimal reset, a high-quality trigger can enhance the shooter’s accuracy and control.

The production of a premium AR15 trigger starts with the selection of quality materials. The materials used in the manufacturing process can greatly impact the durability and performance of the trigger. High-grade steel is often the material of choice for trigger components due to its strength and resistance to wear and tear. Stainless steel, in particular, is a popular choice for trigger sears and hammers because of its corrosion resistance and smooth surface finish.

In addition to steel, other materials such as aluminum and polymer are also used in trigger production. Aluminum is lightweight and has excellent strength-to-weight ratio, making it ideal for trigger housings and other components that require precision machining. Polymer, on the other hand, is used for trigger shoes and other non-critical parts due to its lightweight and cost-effective nature.

The use of quality materials in AR15 trigger production is essential for ensuring consistent performance and longevity. By using high-grade steel and other durable materials, manufacturers can create triggers that can withstand thousands of rounds without compromising on accuracy or reliability. This is especially important for competitive shooters and law enforcement personnel who rely on their firearms to perform flawlessly in high-pressure situations.

In addition to durability, the choice of materials also affects the feel and function of the trigger. A premium AR15 trigger should have a smooth and consistent pull weight, with minimal creep and overtravel. This is achieved through precise machining and fitting of the trigger components, as well as the use of high-quality materials that can withstand the forces exerted during firing.

The importance of quality materials in AR15 trigger production cannot be overstated. By using the right materials, manufacturers can create triggers that are not only durable and reliable but also provide a superior shooting experience for the end user. Whether it’s for competition shooting, hunting, or self-defense, a premium AR15 trigger can make all the difference in accuracy and control.

In conclusion, the making of a premium AR15 trigger is a meticulous process that starts with the selection of quality materials. By using high-grade steel, aluminum, and polymer, manufacturers can create triggers that are durable, reliable, and provide a superior shooting experience. From crisp breaks to minimal reset, a premium trigger can enhance the shooter’s accuracy and control, making it an essential component of any AR15 rifle.

Design Considerations for a Premium AR15 Trigger

When it comes to precision engineering, every detail matters. This is especially true when designing a premium AR15 trigger. The trigger is a critical component of any firearm, as it is responsible for initiating the firing sequence. A high-quality trigger can make all the difference in terms of accuracy, consistency, and overall shooting experience.

One of the key design considerations for a premium AR15 trigger is the material used. The material must be strong, durable, and able to withstand the high levels of stress and pressure that come with firing a rifle. Stainless steel is a popular choice for AR15 triggers due to its strength and corrosion resistance. It is also easy to machine to precise tolerances, which is essential for ensuring a smooth and consistent trigger pull.

Another important design consideration is the shape and geometry of the trigger. The trigger must be ergonomically designed to provide a comfortable and natural feel for the shooter. The shape of the trigger face can also affect the feel of the trigger pull. A flat-faced trigger, for example, can provide a more consistent pull and better control over the shot.

In addition to the shape of the trigger, the weight and pull of the trigger are also crucial design considerations. A premium AR15 trigger should have a light and crisp pull, with minimal creep and overtravel. This allows for quick and precise shots, without the need for excessive force or movement. Adjustable triggers are also popular among shooters, as they allow for customization to suit individual preferences.

The sear engagement and reset of the trigger are also important factors to consider in the design process. The sear engagement refers to the point at which the trigger releases the hammer to fire the round. A clean and consistent sear engagement is essential for accuracy and reliability. The reset of the trigger is the distance the trigger must travel forward after firing before it can be pulled again. A short and positive reset is desirable for rapid follow-up shots.

Overall, the design of a premium AR15 trigger is a complex and intricate process that requires careful consideration of multiple factors. From the material used to the shape and weight of the trigger, every detail must be meticulously planned and executed to ensure optimal performance and user experience.

In conclusion, precision engineering is at the heart of designing a premium AR15 trigger. By carefully considering factors such as material, shape, weight, pull, sear engagement, and reset, engineers can create a trigger that is not only reliable and accurate but also comfortable and enjoyable to use. A high-quality trigger can make a significant difference in the performance of a rifle, and shooters who invest in a premium AR15 trigger can expect improved accuracy, consistency, and overall shooting experience.

Precision Machining Techniques for Enhanced Trigger Performance

Precision engineering is a critical component in the creation of high-quality firearms, such as the AR15. One of the key elements that can greatly impact the performance of an AR15 is the trigger. A premium trigger can make all the difference in accuracy, reliability, and overall shooting experience. In this article, we will explore the precision machining techniques that go into the making of a premium AR15 trigger.

When it comes to crafting a premium AR15 trigger, precision machining is essential. Every component of the trigger must be meticulously manufactured to exact specifications in order to ensure smooth operation and consistent performance. This level of precision requires advanced machinery and skilled craftsmen who are dedicated to producing the highest quality products.

One of the first steps in the manufacturing process is the selection of high-quality materials. Premium AR15 triggers are typically made from materials such as stainless steel or aluminum, which are known for their durability and resistance to wear. These materials are carefully inspected for imperfections before being machined into the various components of the trigger.

Once the materials have been selected, the machining process begins. Precision CNC (Computer Numerical Control) machines are used to cut and shape the components of the trigger with incredible accuracy. These machines are capable of producing parts with tolerances as tight as a few thousandths of an inch, ensuring that each component fits together perfectly.

During the machining process, each component of the trigger is carefully inspected and measured to ensure that it meets the exact specifications required for optimal performance. Any deviations from the design are corrected immediately to maintain the highest level of precision.

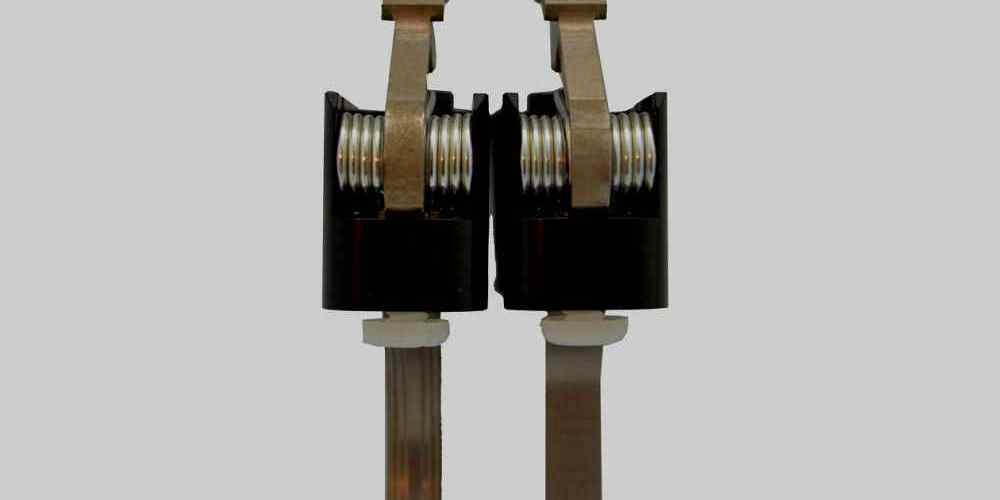

One of the key components of an AR15 trigger is the sear, which is responsible for releasing the hammer and firing the weapon. The sear must be machined to precise dimensions in order to ensure a crisp and consistent trigger pull. This requires careful attention to detail and a thorough understanding of the mechanics of the trigger system.

In addition to the sear, other components of the trigger, such as the trigger shoe and disconnector, must also be machined with precision. These components work together to provide a smooth and reliable trigger pull that is essential for accurate shooting.

After all of the components have been machined to perfection, they are carefully assembled by skilled craftsmen. Each part is fitted together with precision to ensure that the trigger functions flawlessly. The assembled trigger is then tested to ensure that it meets the strict quality standards set by the manufacturer.

In conclusion, precision machining is a critical aspect of creating a premium AR15 trigger. By using advanced machinery and skilled craftsmen, manufacturers are able to produce triggers that offer exceptional performance and reliability. The attention to detail and dedication to quality that goes into the making of these triggers is what sets them apart from the competition. If you are looking to upgrade your AR15, investing in a premium trigger that has been crafted with precision engineering is a wise choice.

Testing and Quality Control Measures for Precision Engineered AR15 Triggers

When it comes to precision engineering, every detail matters. This is especially true when it comes to the manufacturing of AR15 triggers. These small components play a crucial role in the overall performance of the firearm, so it is essential that they are made with the utmost precision and care. In this article, we will take a closer look at the testing and quality control measures that go into the making of a premium AR15 trigger.

One of the first steps in the manufacturing process is the selection of high-quality materials. Premium AR15 triggers are typically made from materials such as stainless steel or aluminum, which are known for their durability and resistance to wear and tear. These materials are carefully inspected for any defects or imperfections before they are used in the production of triggers.

Once the materials have been selected, they are machined to precise specifications using advanced CNC machines. These machines are capable of producing incredibly precise cuts and shapes, ensuring that each trigger is made to exacting standards. After the machining process is complete, the triggers are carefully inspected for any signs of damage or irregularities.

Next, the triggers undergo a series of tests to ensure that they meet the strict quality control standards set by the manufacturer. One of the most important tests is the pull weight test, which measures the amount of force required to pull the trigger. Premium AR15 triggers are typically designed to have a crisp, clean break with minimal creep, so it is essential that the pull weight is within the specified range.

In addition to the pull weight test, the triggers are also tested for consistency and reliability. This involves testing the triggers under various conditions, such as extreme temperatures and humidity levels, to ensure that they will perform reliably in any situation. Any triggers that fail to meet the manufacturer’s standards are rejected and sent back for further inspection or rework.

Once the triggers have passed all of the necessary tests, they are carefully assembled and packaged for shipment. Each trigger is individually inspected to ensure that it meets the manufacturer’s quality control standards before it is sent out to customers. This attention to detail is what sets premium AR15 triggers apart from their competitors and ensures that customers receive a high-quality product that they can rely on.

In conclusion, the testing and quality control measures that go into the making of a premium AR15 trigger are essential for ensuring that each component meets the highest standards of precision and reliability. By using high-quality materials, advanced machining techniques, and rigorous testing procedures, manufacturers can produce triggers that are not only durable and reliable but also provide a superior shooting experience for their customers. So, the next time you’re in the market for a new AR15 trigger, be sure to look for one that has been made with precision engineering in mind.