How to Reload .223 Remington for Accuracy

The .223 Remington is one of the most popular rifle cartridges in the world, favored by hunters, competitive shooters, and tactical marksmen alike. Its versatility, availability, and relatively mild recoil make it an excellent choice for a variety of shooting disciplines. However, achieving pinpoint accuracy with factory ammunition can be limited by mass production variances. This is where handloading or reloading your own .223 Remington rounds becomes invaluable.

Reloading allows shooters to tailor their ammunition to their specific firearm and shooting conditions, resulting in enhanced precision and consistency. In this article, we will explore how to reload .223 Remington for accuracy with a comprehensive guide covering key steps, best practices, and expert tips.

Understanding the Basics of Reloading .223 Remington

Before diving into the technical details of reloading for accuracy, it’s essential to understand the fundamental components and processes involved in creating a reliable round:

- Case: The brass cartridge case which holds all other components together.

- Primer: The ignition source that ignites the powder charge.

- Powder: The propellant that generates gas pressure to propel the bullet forward.

- Bullet: The projectile itself which travels downrange.

Reloading involves assembling these components correctly and consistently to ensure each round performs identically. Any variation in powder charge weight, bullet seating depth, or primer type can affect velocity and accuracy.

The .223 Remington cartridge typically fires bullets ranging from 40 to 77 grains in weight. For precision shooting, many reloaders prefer bullets between 55 and 69 grains due to their favorable ballistic coefficients and stability at common velocities.

Selecting Quality Components for Maximum Accuracy

The foundation of accurate reloading starts with choosing premium components that offer uniformity and reliability. Here are some guidelines when selecting parts for your .223 Remington reloads:

- Brass Cases: Use high-quality brass such as Lapua or Hornady cases known for consistent dimensions and durability. New brass is ideal; however, once-fired cases can be reused if properly inspected and cleaned.

- Primers: Match your powder type with appropriate primers (small rifle primers are standard). Brands like CCI, Federal Gold Medal Match, and Winchester are often recommended for consistent ignition.

- Powder: Choose powders that are known to deliver uniform burn rates suitable for the .223 Remington cartridge. Popular choices include Hodgdon Varget, IMR 8208 XBR, and Alliant AR-Comp — all praised for their temperature stability and clean burning properties.

- Bullets: For precision shooting, select bullets designed specifically for match-grade performance such as Sierra MatchKing, Berger VLD (Very Low Drag), or Hornady A-Max bullets. These bullets maintain consistent aerodynamic profiles aiding long-range accuracy.

A case study by the Precision Rifle Blog found that switching from generic range bullets to Sierra MatchKings improved group sizes by up to 30% at 100 yards in a test rifle chambered in .223 Remington — highlighting the impact bullet selection has on accuracy.

The Reloading Process: Step-by-Step Guide to Consistent Loads

Reloading demands meticulous attention to detail throughout each step of the process. Here’s a detailed breakdown designed specifically for achieving maximum accuracy with your .223 Remington reloads:

1. Case Preparation

-

Inspect Cases: Check every case for cracks, splits, or deformities that could cause failures or inconsistent pressures.

-

Clean Cases: Use ultrasonic cleaners or tumblers with media like walnut shells or corn cob media to remove carbon deposits and residue.

-

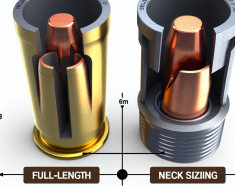

Resize Cases: Using a high-quality full-length resizing die ensures your brass will chamber smoothly in any rifle of the same caliber. Pay attention not to overwork the brass as this can reduce case life.

-

Trim Length: Trim cases uniformly using a case trimmer since variations in length affect seating depth and overall cartridge dimensions. The SAAMI specification calls for a maximum case length of 1.760 inches.

2. Primer Seating

-

Select primers consistent with your load data recommendations—usually small rifle primers such as CCI BR4 or Federal GM205M work well.

-

Use a quality primer seater tool ensuring primers sit flush without crushing or damage which can lead to misfires or inconsistent ignition timing.

3. Powder Charging

-

Select your powder charge based on published load data from reputable sources like Hodgdon or Alliant reloading manuals—never exceed maximum recommended charges without professional advice or pressure testing equipment.

-

If possible, use an electronic scale capable of measuring powder charges to ±0.01 grains; consistent powder charges directly impact velocity consistency and thus accuracy.

4. Bullet Seating

-

<li