“Evolution of AR15 Handguards: From Wood to Polymer, a Historical Journey”

Wood: The Original AR15 Handguard Material

The AR15 is a popular rifle known for its versatility and customization options. One key component of the AR15 is the handguard, which serves as a protective covering for the barrel and allows for the attachment of accessories such as lights, lasers, and grips. Over the years, the materials used to make AR15 handguards have evolved, with wood being the original material of choice.

Wooden handguards were commonly used on early AR15 models, dating back to the 1960s. Wood was a popular choice due to its availability, affordability, and ease of customization. Wood handguards were often made from walnut or birch, and could be stained or painted to match the rifle’s stock.

While wood handguards were functional and aesthetically pleasing, they had some drawbacks. Wood is prone to warping, cracking, and splintering, especially when exposed to harsh weather conditions or rough handling. Additionally, wood handguards were heavier than modern materials, which could affect the overall balance and handling of the rifle.

As technology advanced, manufacturers began to explore alternative materials for AR15 handguards. One of the first materials to gain popularity was aluminum. Aluminum handguards were lightweight, durable, and resistant to corrosion. However, aluminum handguards could become hot to the touch after prolonged use, which could be uncomfortable for the shooter.

In the 1980s, polymer handguards began to emerge as a viable alternative to wood and aluminum. Polymer is a synthetic material that is lightweight, durable, and resistant to heat and corrosion. Polymer handguards are also more affordable to produce than wood or aluminum, making them a cost-effective option for manufacturers and consumers.

Polymer handguards come in a variety of colors and styles, allowing shooters to customize their rifles to their liking. Some polymer handguards are even designed with built-in Picatinny rails for easy attachment of accessories. Polymer handguards are also easy to install, requiring no special tools or expertise.

In addition to their practical benefits, polymer handguards are also environmentally friendly. Unlike wood, which requires the harvesting of trees, polymer is a synthetic material that can be recycled and reused. This makes polymer handguards a sustainable choice for environmentally conscious shooters.

Overall, the progression of AR15 handguard materials from wood to polymer represents a significant advancement in rifle technology. While wood handguards have a classic look and feel, polymer handguards offer superior performance, durability, and customization options. Whether you prefer the traditional appeal of wood or the modern functionality of polymer, there is a handguard material to suit every shooter’s needs and preferences.

Aluminum: The Transition from Wood to Metal

The AR15 rifle has a long and storied history, evolving over the years to become one of the most popular firearms in the world. One of the key components of the AR15 is the handguard, which has undergone significant changes in materials and design since the rifle was first introduced. In this article, we will explore the historical progression of AR15 handguard materials, focusing on the transition from wood to aluminum.

When the AR15 was first developed in the 1950s, the handguard was typically made of wood. Wood was a common material for rifle handguards at the time, as it was readily available, easy to work with, and provided a traditional look and feel to the firearm. However, wood handguards had their limitations. They were prone to warping, cracking, and splintering, especially when exposed to the elements or subjected to heavy use.

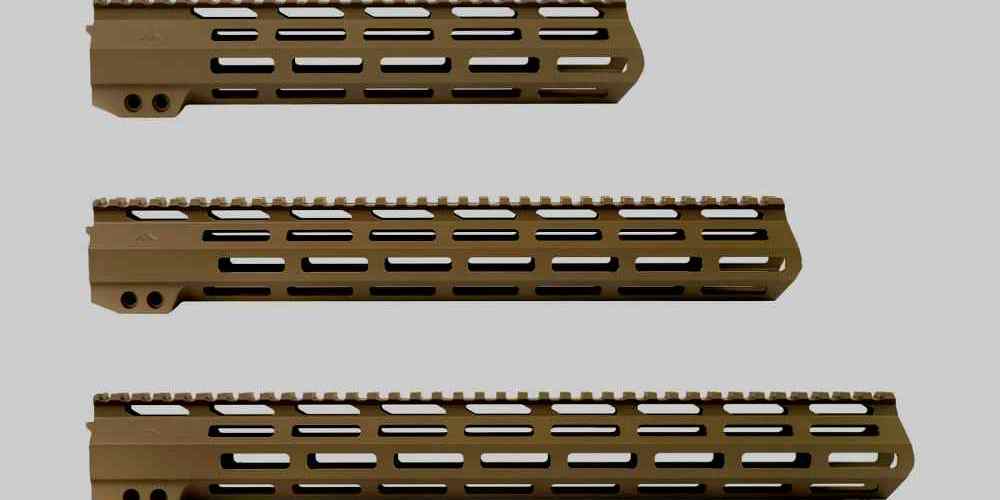

As the AR15 gained popularity and saw increased use in military and law enforcement applications, the need for a more durable and lightweight handguard became apparent. This led to the transition from wood to aluminum as the material of choice for AR15 handguards. Aluminum offered several advantages over wood, including increased strength, resistance to corrosion, and the ability to be easily machined into complex shapes.

The transition from wood to aluminum handguards marked a significant milestone in the evolution of the AR15. Aluminum handguards were not only more durable and lightweight than their wooden counterparts, but they also allowed for the integration of additional features such as Picatinny rails for mounting accessories like optics, lights, and grips. This made the AR15 more versatile and adaptable to a wide range of mission requirements.

In addition to its practical advantages, aluminum handguards also gave the AR15 a more modern and tactical appearance. The sleek lines and matte finish of aluminum handguards added to the rifle’s aesthetic appeal, making it a favorite among shooters and collectors alike. The transition to aluminum handguards helped solidify the AR15’s reputation as a cutting-edge firearm that was ahead of its time.

Today, aluminum remains one of the most popular materials for AR15 handguards, thanks to its combination of strength, durability, and versatility. However, advancements in materials science have led to the development of new materials that offer even greater performance benefits. One such material is polymer.

Polymer handguards are made from a lightweight and durable synthetic material that offers many of the same advantages as aluminum, such as resistance to corrosion and the ability to be easily molded into complex shapes. However, polymer handguards are typically lighter than aluminum handguards, making them a popular choice for shooters who prioritize weight savings and maneuverability.

The transition from wood to aluminum to polymer handguards represents the ongoing evolution of the AR15 platform. Each material has its own unique advantages and characteristics, allowing shooters to customize their rifles to suit their individual preferences and needs. Whether you prefer the classic look of wood, the modern appeal of aluminum, or the lightweight performance of polymer, there is a handguard material that is sure to meet your requirements.

In conclusion, the transition from wood to aluminum to polymer handguards has played a significant role in the historical progression of the AR15. Each material has brought its own set of advantages and innovations to the platform, helping to make the AR15 one of the most versatile and adaptable firearms on the market. As technology continues to advance, we can expect to see even more advancements in materials and design that will further enhance the performance and capabilities of the AR15.

Polymer: The Modern Material of Choice for AR15 Handguards

The AR15 is a popular rifle platform known for its versatility and customization options. One key component of the AR15 is the handguard, which serves as a protective covering for the barrel and allows for the attachment of accessories such as lights, lasers, and grips. Over the years, the materials used to make AR15 handguards have evolved, with polymer emerging as the modern material of choice.

In the early days of the AR15, handguards were typically made of wood. Wood handguards were durable and provided a classic look to the rifle. However, they were heavy and could warp or crack over time, especially with exposure to moisture and other environmental factors. As technology advanced, manufacturers began to explore alternative materials that offered improved performance and durability.

One of the first materials to replace wood in AR15 handguards was aluminum. Aluminum handguards were lightweight and offered better heat dissipation than wood. However, they were prone to scratching and could become uncomfortably hot to the touch during extended firing sessions. Additionally, aluminum handguards lacked the customization options that polymer handguards would later provide.

Polymer handguards began to gain popularity in the 1990s as advancements in materials science allowed for the development of high-strength, lightweight polymers. Polymer handguards offer several advantages over traditional materials such as wood and aluminum. They are lightweight, durable, and resistant to heat and corrosion. Polymer handguards also provide a high degree of customization, with manufacturers offering a wide range of colors, textures, and accessory mounting options.

One of the key benefits of polymer handguards is their ability to withstand high temperatures without becoming uncomfortably hot to the touch. This is especially important for shooters who engage in rapid-fire or sustained fire exercises. Polymer handguards also offer improved ergonomics, with many models featuring contoured shapes and textured surfaces for a more comfortable grip.

In addition to their performance benefits, polymer handguards are also more cost-effective to produce than wood or aluminum handguards. This has made them a popular choice among budget-conscious shooters who still want a high-quality, reliable handguard for their AR15. Polymer handguards are also easier to install and maintain, with many models requiring no special tools for installation.

Overall, polymer handguards have become the modern material of choice for AR15 owners looking for a lightweight, durable, and customizable handguard for their rifle. With advancements in materials science continuing to push the boundaries of what is possible, it is likely that polymer handguards will only continue to improve in the years to come. Whether you are a competitive shooter, a law enforcement officer, or a recreational gun owner, a polymer handguard can provide the performance and reliability you need to get the most out of your AR15 rifle.

Advantages of Polymer Handguards over Wood and Aluminum

The AR15 rifle has been a staple in the firearms industry for decades, known for its versatility and customization options. One key component of the AR15 is the handguard, which serves as a protective covering for the barrel and gas system. Over the years, the materials used to make AR15 handguards have evolved, with wood and aluminum being the traditional choices. However, in recent years, polymer handguards have gained popularity due to their numerous advantages over wood and aluminum.

One of the main advantages of polymer handguards is their lightweight nature. Wood handguards, while aesthetically pleasing, can be heavy and cumbersome, affecting the overall balance of the rifle. Aluminum handguards, on the other hand, are lightweight but can be prone to heat retention, making them uncomfortable to hold during extended shooting sessions. Polymer handguards strike the perfect balance between weight and heat dissipation, making them a popular choice among AR15 enthusiasts.

In addition to being lightweight, polymer handguards are also incredibly durable. Wood handguards can be prone to cracking and warping over time, especially when exposed to harsh weather conditions. Aluminum handguards are more durable than wood but can still dent and scratch easily. Polymer handguards, on the other hand, are resistant to cracking, warping, dents, and scratches, making them a long-lasting and reliable option for AR15 owners.

Another advantage of polymer handguards is their affordability. Wood handguards can be expensive, especially if you opt for high-quality, exotic woods. Aluminum handguards are also pricey, as the material itself is more costly to produce. Polymer handguards, on the other hand, are relatively inexpensive to manufacture, making them a budget-friendly option for those looking to customize their AR15 without breaking the bank.

Despite their affordability, polymer handguards do not sacrifice on aesthetics. Modern manufacturing techniques have allowed for polymer handguards to be produced in a wide range of colors and patterns, allowing AR15 owners to customize their rifles to their liking. Whether you prefer a sleek black handguard or a vibrant camo pattern, there is a polymer handguard out there to suit your style.

In conclusion, polymer handguards offer numerous advantages over traditional wood and aluminum handguards. Their lightweight nature, durability, affordability, and customizable options make them a popular choice among AR15 enthusiasts. Whether you are a seasoned shooter looking to upgrade your rifle or a beginner looking to personalize your AR15, polymer handguards are a versatile and practical option to consider. So next time you are in the market for a new handguard, consider making the switch from wood or aluminum to polymer and experience the benefits for yourself.

The Future of AR15 Handguard Materials: Innovations and Trends

The AR15 is a popular rifle platform known for its versatility and customization options. One key component of the AR15 is the handguard, which serves as a protective covering for the barrel and allows for the attachment of accessories such as lights, lasers, and grips. Over the years, the materials used to make AR15 handguards have evolved, from traditional wood to modern polymers. This article will explore the historical progression of AR15 handguard materials and discuss the future of handguard materials, including innovations and trends.

In the early days of the AR15, handguards were typically made of wood. Wood was a common material for rifle stocks and handguards due to its availability and ease of shaping. However, wood handguards had limitations in terms of durability and weight. As the AR15 platform evolved and became more popular, manufacturers began to explore alternative materials for handguards.

One of the first materials to replace wood in AR15 handguards was aluminum. Aluminum handguards offered improved durability and heat resistance compared to wood. However, aluminum handguards were heavier than wood and could become uncomfortably hot to the touch during extended shooting sessions. Despite these drawbacks, aluminum handguards were a significant improvement over wood in terms of performance and longevity.

In the 1980s, polymer handguards began to gain popularity as an alternative to aluminum. Polymers are synthetic materials that are lightweight, durable, and resistant to heat and corrosion. Polymer handguards offered all the benefits of aluminum handguards without the added weight and heat retention. Additionally, polymer handguards could be easily molded into different shapes and designs, allowing for greater customization options.

Today, polymer handguards are the most common choice for AR15 owners. Polymer handguards are available in a wide range of colors, textures, and designs, allowing shooters to personalize their rifles to their liking. Polymer handguards are also more affordable than aluminum handguards, making them a popular choice for budget-conscious shooters.

Looking to the future, the trend in AR15 handguard materials is towards advanced composites and hybrid materials. Advanced composites are materials made from a combination of different substances, such as carbon fiber, fiberglass, and Kevlar. These materials offer superior strength, durability, and heat resistance compared to traditional polymers.

Hybrid materials, such as polymer-aluminum blends, are also gaining popularity in the AR15 market. These materials combine the lightweight and customizable properties of polymers with the strength and heat resistance of aluminum. Hybrid materials offer the best of both worlds, providing shooters with a durable and high-performance handguard option.

Innovations in manufacturing techniques, such as 3D printing and injection molding, are also driving the evolution of AR15 handguard materials. These technologies allow for the production of complex and lightweight handguard designs that were previously impossible to achieve. As technology continues to advance, we can expect to see even more innovative and high-performance handguard materials in the future.

In conclusion, the progression of AR15 handguard materials from wood to polymer has been a testament to the ingenuity and innovation of the firearms industry. Today, shooters have a wide range of handguard materials to choose from, each offering unique benefits and customization options. As technology continues to advance, we can expect to see even more exciting developments in AR15 handguard materials in the years to come.