Reloading for Cast Bullet Accuracy: Unlocking Precision with Traditional Projectiles

Reloading for cast bullet accuracy is a specialized art within the broader discipline of handloading ammunition. While jacketed bullets dominate much of the shooting world, cast bullets offer unique advantages and challenges that require careful attention to detail. This article delves into the fundamentals and nuances of reloading for cast bullet accuracy, providing shooters with practical insights and techniques to maximize precision.

The Appeal and Challenges of Cast Bullets

Cast bullets have been used since the early days of firearms, long before the advent of modern jacketed projectiles. Their enduring appeal lies in several key factors:

- Cost-effectiveness: Cast bullets can be made at home or purchased inexpensively compared to jacketed bullets, making them attractive for high-volume shooting and target practice.

- Reduced barrel wear: Lead bullets are gentler on barrels than copper-jacketed ones, extending barrel life.

- Customization: Shooters can mold their own bullet shapes and sizes to match specific firearms.

- Traditional shooting disciplines: Many cowboy action shooters, vintage rifle enthusiasts, and hunters prefer cast bullets for authenticity and historical accuracy.

However, reloading for cast bullet accuracy is not without its challenges. Lead bullets require precise control over factors such as alloy hardness, bullet lubrication, seating depth, and powder charge. Additionally, cast bullets typically operate at lower velocities due to lead’s lower melting point and risk of leading barrels if pushed too fast.

Understanding Bullet Casting: The Foundation of Accuracy

The first step toward accurate cast bullet reloading is understanding the casting process itself. The quality and characteristics of your bullet directly affect accuracy. Here are several key considerations:

- Alloy composition: Most reloaders use a lead-tin-antimony alloy to increase hardness. A common recipe is 80% lead, 15% antimony, and 5% tin. Antimony adds hardness and improves casting quality; tin enhances fluidity.

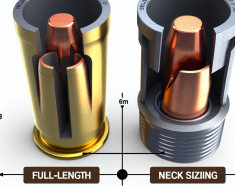

- Bullet sizing: Properly sized bullets engage the rifling consistently. Bullets should be sized slightly larger than the bore diameter — typically .001″ to .003″ larger — depending on barrel condition and intended velocity.

- Lubrication: Cast bullets require lubrication to reduce leading (lead deposits in the barrel) and friction. Popular lubricants include traditional wax-based lube or modern synthetic blends designed for clean burning.

- Mold quality: High-quality molds produce uniform bullets with consistent weight and dimensions — critical for precision shooting.

A case study from a precision shooter’s forum highlights this: when switching from pure lead to a hard-cast alloy (with added antimony), group sizes improved by nearly 40%, illustrating how critical alloy hardness can be for stable flight characteristics.

Powder Selection and Charge Weight: Balancing Velocity and Consistency

The choice of powder type and charge weight significantly impacts cast bullet accuracy. Unlike jacketed bullets that often tolerate higher velocities, cast bullets excel within moderate velocity ranges to prevent leading and maintain stability.

- Pistol powders for handgun calibers: For calibers like .38 Special or .45 ACP using cast bullets, slower-burning pistol powders such as Hodgdon Titegroup or Accurate No.7 are popular choices. These powders provide smooth pressure curves conducive to consistent velocities without excessive pressure spikes.

- Smokeless rifle powders for rifle calibers: In rifle calibers like .30-30 Winchester or .45-70 Government with cast projectiles, medium burn rate powders such as IMR 4198 or Hodgdon H4895 are preferred. They offer good metering characteristics and manageable pressures at moderate velocities.

- Avoiding excessive velocity: Exceeding approximately 1,200 feet per second (fps) in handgun rounds or around 2,000 fps in rifle rounds with cast bullets risks leading barrels or damaging projectiles due to heat buildup from friction.

A quantitative study by a well-known ballistics laboratory found that increasing velocity beyond recommended limits resulted in exponential increases in barrel leading — reducing both accuracy and barrel life. Thus, maintaining optimal velocities tailored to your bullet design is essential.

The Importance of Seating Depth and Cartridge Overall Length (COL)

The position of the bullet within the cartridge case influences chamber pressure dynamics and alignment with the rifling — both critical to achieving tight groups with cast bullets.

- Bore riding vs. freebore seating: Some shooters prefer seating their cast bullets so that they just touch or slightly “bore ride” the rifling upon chambering; others leave a small freebore gap (~0.020″–0.050″) before contact. Both methods have advocates depending on firearm design.

- Tuning COL for accuracy: Small variations in seating depth can dramatically affect group size by changing how the bullet engages rifling upon firing. Experimenting with incremental COL changes while monitoring pressure signs helps find an optimal setting.

- Avoiding excessive pressures: Seating too deep can increase pressures beyond safe limits due to reduced case volume; conversely seating too shallow may impair ignition consistency.

</ul