Reloading Dies: Full-Length vs Neck Sizing Explained

Reloading ammunition is a rewarding and cost-effective practice embraced by many shooting enthusiasts, hunters, and competitive marksmen. One of the critical decisions in the reloading process is choosing between full-length sizing and neck sizing dies. Each method has its proponents, advantages, and limitations that can significantly impact cartridge performance, accuracy, and longevity of brass cases.

In this comprehensive article, we will explore the differences between full-length and neck sizing dies, delve into their pros and cons, provide practical examples, and discuss when each method is most appropriate. By the end, you will have a clear understanding of which reloading die system best suits your needs.

Understanding Reloading Dies: What Are They?

Before diving into full-length versus neck sizing, it’s essential to understand what reloading dies do in general. Reloading dies are precision tools used in conjunction with a reloading press to resize fired brass cases so they can be safely chambered again in a firearm.

When a cartridge is fired, the brass case expands inside the chamber to seal the gases generated by the ignited powder. This expansion slightly alters the dimensions of the brass case, particularly around the body and neck areas. Reloading dies restore these dimensions to ensure consistent chambering and reliable pressure containment during subsequent firings.

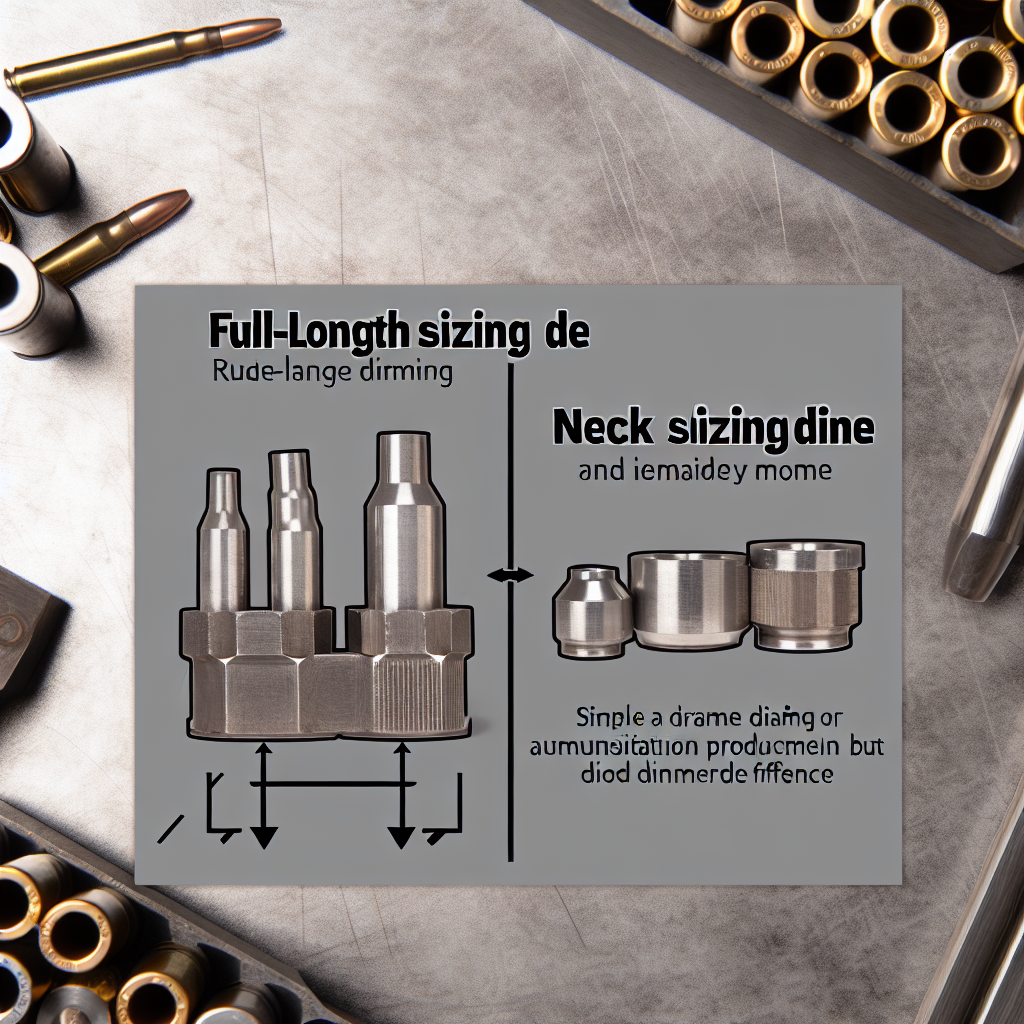

- Full-length sizing dies: Resize the entire case body and neck back to original factory dimensions.

- Neck sizing dies: Only resize the neck portion of the case while leaving the body mostly unchanged.

Full-Length Sizing Explained

Full-length sizing is the traditional and most commonly used method for resizing brass cases. The full-length sizing die pushes the entire case back to its original factory specifications. This means resizing both the neck (which holds the bullet) and the body (which fits into the chamber).

This process ensures that each case will chamber easily in any firearm of that caliber because all dimensions conform to SAAMI (Sporting Arms and Ammunition Manufacturers’ Institute) standards or equivalent specifications.

How Full-Length Sizing Works

The full-length sizing die has an internal mandrel or expander ball that guides resizing:

- The case is inserted into the die.

- The press ram pushes the case up into contact with the die’s internal components.

- The die resizes both body and neck back to factory specs.

- An expander ball passes through the neck to maintain proper neck diameter after resizing.

Advantages of Full-Length Sizing

- Chamber compatibility: Cases resized full-length will chamber reliably in any firearm of that caliber, making them ideal for sharing ammo among multiple guns or selling ammo to others.

- Longevity: Resizing removes any expansion or distortion from firing cycles, reducing risk of stuck cases or unsafe pressures on subsequent reloads.

- Consistency: Creates uniform cartridges that meet industry standards for dimension and pressure containment.

Potential Drawbacks

- Brass life reduction: Full-length resizing stretches brass more aggressively, leading to faster work-hardening and shorter case life compared to neck sizing.

- Slight loss in accuracy: Some shooters report minor decreases in accuracy because full-length sizing can alter how well a case fits their specific chamber’s unique dimensions.

Neck Sizing Explained

Neck sizing is a more specialized method where only the neck of a fired cartridge is resized. The body remains largely untouched from firing dimensions. This approach maintains some degree of “fire-formed” fit between brass and chamber, which can enhance accuracy but limit cartridge interchangeability between firearms.

How Neck Sizing Works

The neck sizing die functions by:

- The case is pushed into the die similarly to full-length sizing but only contacts an internal mandrel or expander ball at the neck region.

- The neck diameter is returned close to factory specs so it can hold a bullet securely again without stretching excessively upon seating.

- The body retains its slightly expanded fire-formed shape from previous firings.

Advantages of Neck Sizing

- Improved accuracy: Because fire-formed brass fits your specific rifle’s chamber perfectly, retaining this shape often results in more consistent bullet alignment, better concentricity, and improved shot-to-shot precision.

- Extended brass life: Less stretching reduces fatigue on brass cases; shooters have reported being able to reload cases up to 10-15 times using neck sizing before replacement becomes necessary.

- Lighter press effort: Less resistance during resizing makes it easier on your reloading equipment and speeds up batch processing times.

Drawbacks of Neck Sizing

- Lack of interchangeability: Neck-sized cases may not chamber reliably in different rifles due to retained fire-formed shape variations. This limits ammo sharing or resale potential.

- Tendency for stuck cases: